ModuleWorks, the leading supplier of CAD/CAM components for toolpath generation and simulation, is pleased to announce the latest release of its CAM components, ModuleWorks 2015.12, the third major update of 2015. Each ModuleWorks release contains many new and enhanced features across the product range. This latest version includes new features for 5-Axis, 3-Axis and Simulation.

ModuleWorks is at the forefront of 5-Axis machining and simulation technology, providing the toolpath and simulation technology that powers many of the leading CAM systems available around the world today.

Highlights of the new release are shown below:

5-Axis Machining

Automatic spine creation for port machining has also been enhanced. If the spine gets too close to the machining surface at any point, the toolpath with full collision checking is now created up to that point.

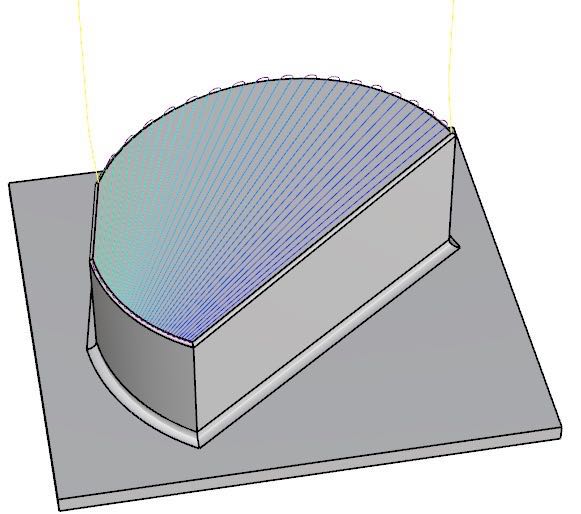

| When a surface extends beyond the ends of a curve, the new Extend curves feature automatically extends the curves. This prevents unwanted wrap-around of the toolpath, improves the pattern and saves time by eliminating the need to manually extend the curves.

A new projection method is provided for Geodesic machining. The containment curve is now projected in the surface normal direction for the selected machining surfaces. |

Extend curves Extend curves |

3-Axis Machining

New trimming criteria provide more efficient processing of cusps near the containment curve by preserving all the cuts where the tool contact points are inside the curve.

| With the new Multiple stock to leave feature, users can define different rest material thicknesses for different machining surfaces. This is particularly important for mold and die production that involve multiple machining steps with heat treatment in between.

The enhanced roughing algorithms speed up the roughing calculation by 25% on average, and up to 50% in some cases. |

Multiple machining surface offsets Multiple machining surface offsets |

Simulation

The quality of the machined surface has also been improved through the implementation of a new normal computation method.

| A new feature for spindle clamps gives you the option to make them transparent when the spindle is rotating.

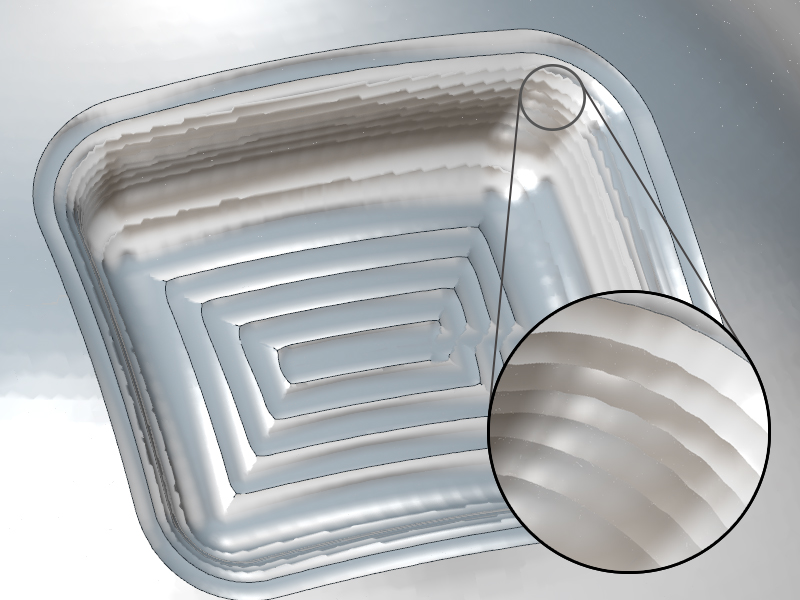

The new automatic quality improvement feature refines the accuracy of the stock model whenever the cutting simulation is idle. This improves accuracy and saves time because there is no need for manual refinement. |

Automatic quality improvements Automatic quality improvements |

The 2015.12 release will be available to all partners at the end of December 2015 from www.ModuleWorks.com.