ModuleWorks, the leading supplier of CAD/CAM components for toolpath generation and simulation, announces the latest release of its CAM components, ModuleWorks 2017.08, the second major update of 2017. Each ModuleWorks release contains many new and enhanced features across the product range. This latest version is now available with new Geodesic and Deburring features for 5-Axis machining as well as a range of further features for 5-Axis, 3-Axis, Turning and Simulation. ModuleWorks is at the forefront of 5-Axis machining and simulation technology, providing the toolpath and simulation technology that powers many of the leading CAM systems available around the world today. Highlights of the new release are shown below:

ModuleWorks, the leading supplier of CAD/CAM components for toolpath generation and simulation, announces the latest release of its CAM components, ModuleWorks 2017.08, the second major update of 2017. Each ModuleWorks release contains many new and enhanced features across the product range. This latest version is now available with new Geodesic and Deburring features for 5-Axis machining as well as a range of further features for 5-Axis, 3-Axis, Turning and Simulation. ModuleWorks is at the forefront of 5-Axis machining and simulation technology, providing the toolpath and simulation technology that powers many of the leading CAM systems available around the world today. Highlights of the new release are shown below:

5-Axis Machining

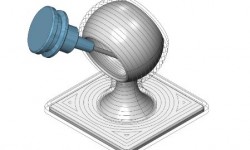

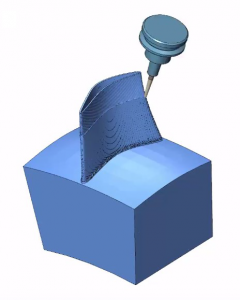

Geodesic machining

The Geodesic toolpath processor is the next evolution in constant step-over pattern generation. It uses a global distance field without a fixed direction of reference to enable full flexibility for calculating different pattern types while maintaining consistent distances between the cuts, even for undercuts.

Geodesic features include:

• Automatic creation of guide curves based on the input geometry

• More supported geometries for the morph pattern

• Boundary detection for guide and containment curves

• Extensions and hole filling to avoid edge rolling

• Guide curve extension to extend short curves to the surface boundary

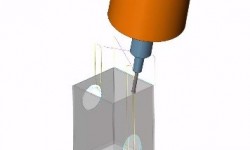

Deburring

The new deburring module creates a deburring toolpath on the outer edges of a part’s geometry. This eliminates the need for time-consuming manual deburring and means the entire toolpath is now generated fully automatically by simply selecting the part’s geometry.

The deburring module includes:

• Automatic feature detection

• Automatic linking

• Automatic lead in

• Automatic collision avoidance.

3-Axis Machining

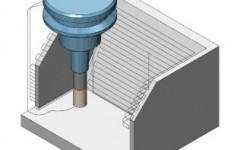

Collision safe areas for finishing

This new feature automatically filters out all the cuts where collisions between the entire tool (including the holder and arbor) and the machining surfaces have been detected.

Fixture curves for roughing

This feature enables users to provide the fixture contours used for the toolpath calculation to avoid collisions between the tool and the fixtures.

Turning

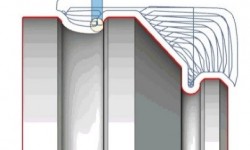

Adaptive roughing

The innovative adaptive roughing strategy guarantees a stable tool load which makes it possible to:

• increase the material removal rate at higher feed rates

• reduce the overall machining time

• extend the tool life

Simulation

Hybrid simulation/manufacturing – Backplotting for 3D printing and additive material simulation

The new Hybrid simulation/manufacturing software consists of two components:

• High-performance backplotting for 3D printing with layer interval analysis that provides a representation of the additive process without material deposition.

• Material deposition that shows material deposition and material removal simultaneously. The resulting part can be exported as a mesh or stl file.

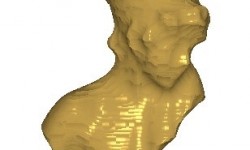

GPU-Shader quality improvement

This feature uses the full power of the GPU to improve the quality of the cut material. It uses a shader (a computer program that performs shading, i.e. produces lighting and shadows in 3D modeling and performs post-processing) to calculate rendering effects on graphics hardware with a high degree of flexibility. The results can be exported as a mesh. The GPU shader refines each screen pixel to allow users to zoom in extremely close and still see the full detail. This feature is an extension and easy to integrate into existing ModuleWorks CutSim features. For further details about the 2017.08 release, see the ModuleWorks YouTube videos.

About ModuleWorks

ModuleWorks is a software component provider for the CAD/CAM industry. ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the CAM industry and its software components and development services are used by the majority of the leading CAM vendors for sophisticated industry focused solutions across diverse business sectors. ModuleWorks 5-Axis and Simulation software has been used in the manufacture of complex parts for over a decade and they have many users across the global CAD/CAM industry.