Additive manufacturing and automated post machining of freeform biodegradable magnesium implants - AdPro

Project start: Oct 2018

Project end: Sep 2021

Details

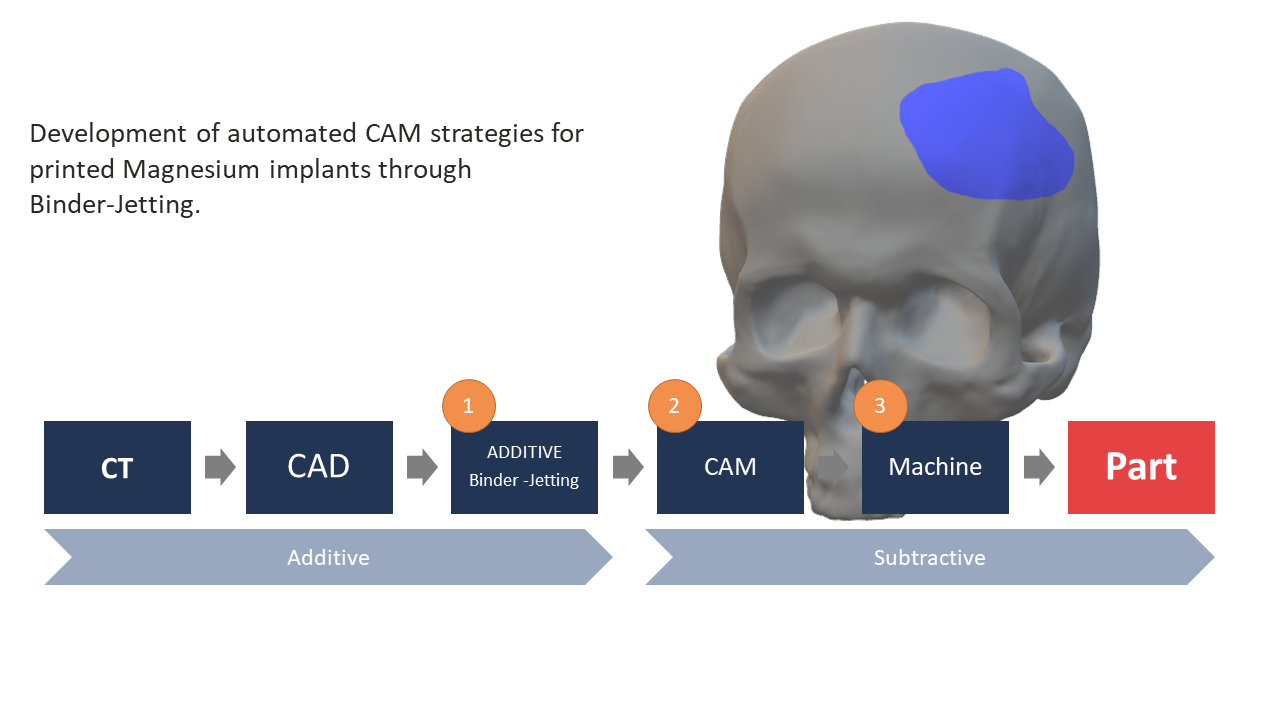

The common goal of the joint project AdPro is the design and development of a Manufacturing process chain consisting of additive manufacturing and subsequent reworking by Milling for the production of individual, biologically resorbable magnesium implants. Magnesium is a quite new material for implants, which has different advantages. The implants will be manufactured by using binder jetting and threated by using sinthering after building process. During sinthering the geometry of the implant will be reduced, but needs to fit the requirements.

The goal of ModuleWorks is the development of an automated and adaptive tool path planning for the milling process. Within the framework of the joint project, a CAM plug-in will be implemented, which automatically carries out tool path planning independent of the implant geometry.

Funding Note

The research and development project “AdPro – Additive manufacturing and automated post machining of freeform biodegradable magnesium implants” is funded by the German Federal Ministry of Education and Research (BMBF) under the Directive on the Promotion of Strategic Project Funding with the Republic of Singapore with the Participation of Science and Industry (“2 + 2” projects) on the priority topic “Advanced Production Technologies” under the number “01DP18008B” and is supervised by the Project Management Agency DLR.

Funding agency