Industrialization of digital engineering and additive manufacturing (AM)

The research and development project “Industrialisierung von Digitalem Engineering und Additiver Fertigung” is funded by the Federal Ministery for Education and Research under the project no.: 13N15004.

Details

The overall objective of the “Industrialization of Digital Engineering and Additive Manufacturing (AM) – IDEA” is the industrialization of additive manufacturing for the German industry by realizing a fully integrated, automated AM production line. By this measure, the biggest challenge facing variant-rich series production is to be accepted and successfully solved: the lack of line integration.

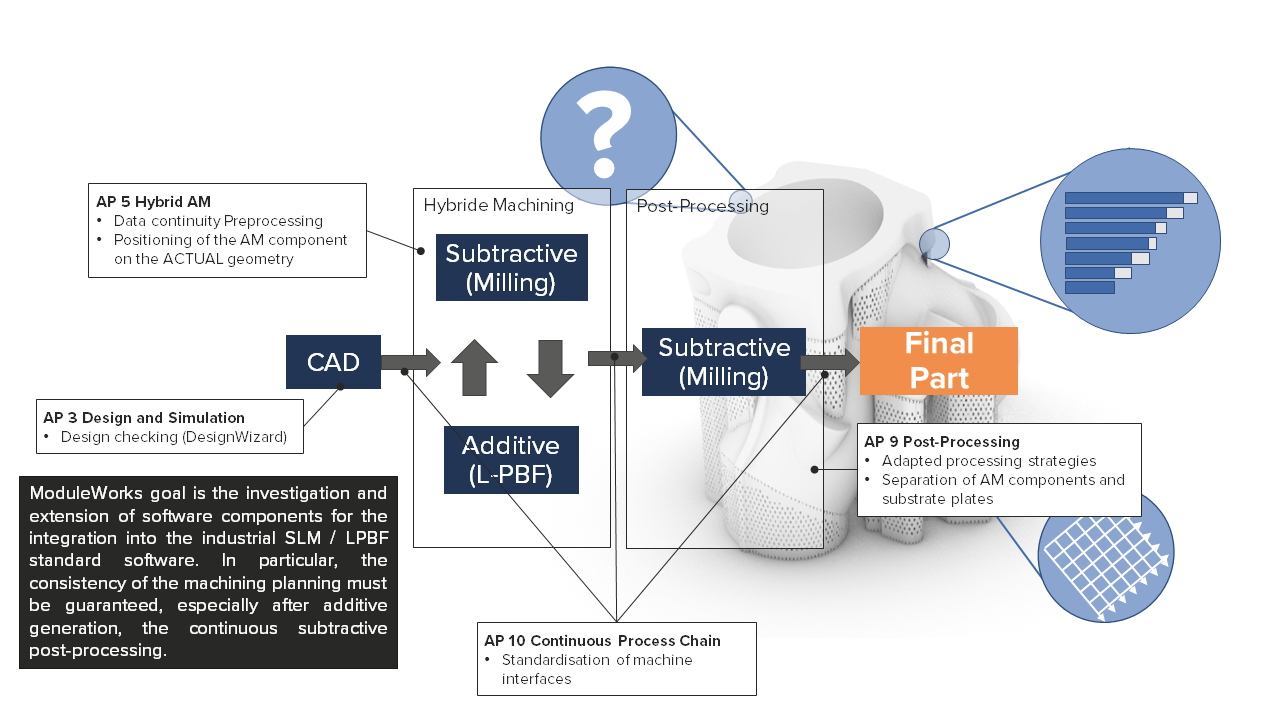

ModuleWorks’ subgoal is the investigation and extension of software components for the integration into the industrial standard software. In particular, the consistency of the machining planning is to be guaranteed, i.e. after additive generation the continuous subtractive post-processing.

To facilitate the planning of additive machining, a system for checking the target geometry during the design in CAD is being developed. This system helps the user to design his designs for the L-PBF process already during the design phase and thus to schedule the process in an optimized way.

For a line integration of the L-PBF, the interaction with further processing steps is another important aspect supported by ModuleWorks. For the alternation between additive and subtractive machining, called hybrid machining, ModuleWorks is researching a system that allows this alternation while planning. During planning, this system constantly tracks the current, virtual shape of the workpiece and makes it available to the machining plans.

An efficient integration of the post-processing into the additive production line requires that the downstream machining strategies are adapted to the L-PBF process in order to effectively use the knowledge available. For example, the distinction between planned volume and support structures. Within this context, ModuleWorks researches optimized machining strategies that enable the removal of these unwanted structures from the virtual line without complex planning.

Partners

- Fraunhofer-Institut für Produktionstechnik IPT

- Siemens AG Power and Gas Division

- MTU Aero Engines AG

- Fraunhofer-Institut für Lasertechnik ILT

- Liebherr-Aerospace Lindenberg GmbH

- MBFZ toolcraft GmbH

- EOS GmbH

- TRUMPF Laser- und Systemtechnik GmbH

- BCT Steuerungs- und DV-Systeme GmbH

- JENAOPTIK AG

- MATRIX GmbH Stuttgart

- Lehrstuhl für Digitale Additive Produktion DAP

- Werkzeugmachinenlabor der RWTH-Aachen (WZL)