ModuleWorks, the leading supplier of CAD/CAM software components for machining and simulation, and ZEISS, an internationally leading technology enterprise operating in the fields of optics and optoelectronics, have combined conventional CAM features and the requirements of ultra-precision machining in a single CAD/CAM software solution.

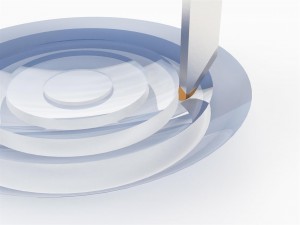

Ultra-precision machining is used for parts that need to be machined to an accuracy of just a few µm and a roughness in the range of nm. Optical parts require both types of machining, ultra-precision machining for the optically effective areas of the part and conventional machining for the non-optical areas. ModuleWorks has developed CAM software components that enabled ZEISS to combine both types of machining in a single, integrated solution. Integrating all machining relevant processes in a unified system accelerates process programming for cutting complex freeform surfaces and improves the quality and cost-efficiency of producing ultra-precision optical parts.

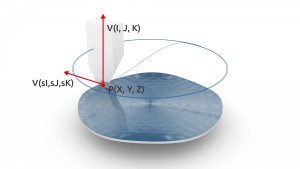

The new software is powered by the ModuleWorks 64-bit ultra-precision kernel. The kernel is based on the industry proven ModuleWorks 5-axis technology for toolpath generation and has been specially developed to meet the growing demand for high-precision machining of increasingly complex geometries in the optics industry. The ModuleWorks ultra-precision kernel supports point clouds, NURBS surfaces and parametric geometries and uses multi-threading for fast toolpath generation with radial, spiral and parallel patterns for slow and fast tool kinematics. The freely configurable machine model supports all machine tool types for grinding and diamond turning applications as well as grinding patterns for roughing, drilling, chamfering, slotting and contouring.

Full 3D machine and material removal simulation software can also be applied with the high resolution of ultra-precision machining requirements. The high-performance CNC posting framework provides scriptable CNC data output at a rate of 50K points per second and supports multi-threaded cloud posting.

“We developed a system to address the needs of UPM and integrated this into a unified CAD/CAM solution for improved efficiency”, explains Lothar Glasmacher, Project Director for Process Technology at ModuleWorks. “The benefits of being able to program complexly shaped geometries including optical functional surfaces within one system can be seen today. This will become even more important for future developments in the light of advanced machining patterns, new 5-axis and 6-axis processes and automation in production machining.”

The software is the result of research and development projects between ZEISS, ModuleWorks and Fraunhofer IPT. It was presented at the euspen 2018 International Conference & Exhibition (4-8 June) in Venice and is available now as a software library that can be integrated into existing CAD/CAM systems. A full demonstration version is currently being implemented in the ModuleWorks Rhino CAM plugin.

About ModuleWorks

ModuleWorks is a software component provider for the CAD/CAM industry. ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the CAM industry and its software components and development services are used by the majority of the leading CAM vendors for sophisticated industry focused solutions across diverse business sectors. The ModuleWorks optics kernel applies this technology to the ultra-precision machining of optical parts, bringing the benefits to a new set of end users. ModuleWorks 5-Axis and Simulation software has been used in the manufacturing of complex parts for over a decade and has many users across the global CAD/CAM industry.

About ZEISS

ZEISS is an internationally leading technology enterprise operating in the optics and optoelectronics industries. The ZEISS Group develops, produces and distributes measuring technology, microscopes, medical technology, eyeglass lenses, camera and cinema lenses, binoculars and semiconductor manufacturing equipment. With its solutions, the company constantly advances the world of optics and helps shape technological progress. ZEISS is divided up into the four segments Research & Quality Technology, Medical Technology, Vision Care/Consumer Products and Semiconductor Manufacturing Technology. The ZEISS Group is represented in more than 40 countries and has over 50 sales and service locations, more than 30 manufacturing sites and about 25 research and development centers around the globe.

In fiscal year 2016/17 the company generated revenue approximating €5.3 billion with around 27,000 employees. Founded in 1846 in Jena, the company is headquartered in Oberkochen, Germany. Carl ZEISS AG is the strategic management holding company that manages the ZEISS Group. The company is wholly owned by the Carl ZEISS Stiftung (Carl ZEISS Foundation)

ZEISS – Contact:

Lutz Autschbach

Tel: +49 7364 20 3358

Email: lutz.autschbach@zeiss.com