ModuleWorks, the leading supplier of CAD/CAM components for toolpath generation and simulation, announces the latest release of its CAM components, ModuleWorks 2016.12, the third major update of 2016. Each ModuleWorks release contains many new and enhanced features across the product range. This latest version includes new features for 5-Axis, 3-Axis, Turning and Simulation.

ModuleWorks is at the forefront of 5-Axis machining and simulation technology, providing the toolpath and simulation technology that powers many of the leading CAM systems available around the world today.

Highlights of the new release are shown below:

5-Axis Machining

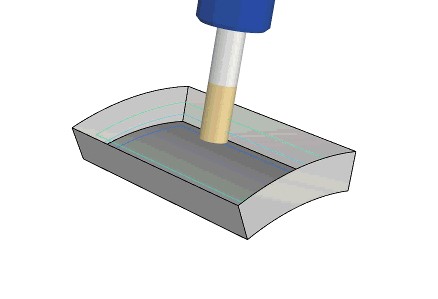

The new advanced engagement options for port machining reduce the cutting load at the beginning of the port machining process.

• Edge rolling ensures the tool enters the port smoothly and gradually.

• Approach and retract ramps can be applied to each side of the geometry for gradual and safe approach and retraction of the tool.

• A maximum overlap can be applied to optimize the distance between two toolpath segments.

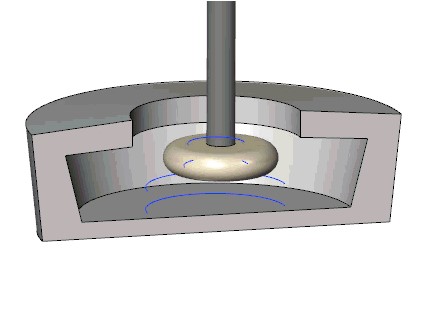

The roughing operation for rotary machining has two new methods:

• Offset – this method defines parallel steps along the rotational axis on the entire machined surface.

• Spiral – the roughing process automatically chooses spiral cuts based on machine conditions to ensure the cuts are performed only in a safe environment without collisions.

| Swarf machining can now be used as a 4-Axis solution. The tool orientation is aligned for a complete 4-Axis cycle. This enables 4-Axis Swarf tilting to be applied to parts that need to be machined with a 5-Axis operation. |  SWARF – 4-Axis tilting SWARF – 4-Axis tilting |

3-Axis Machining

The shape of the holder and arbor are now also taken into consideration during the toolpath calculation to avoid collisions between the entire tool and machining surfaces. This further improves the quality of the toolpaths and reduces the number of modifications to the cutting program.

A new High Speed Machining Pencil cycle accelerates corner and fillet processing using single or multi pencil cuts.

| A new undercutting process provides greater access from a single direction to minimize the number of operations in different machining directions. |  3-Axis undercut machining with Constant Z pattern 3-Axis undercut machining with Constant Z pattern |

Simulation

Color coding of objects according to collision group improves visualization by enabling users to see selected geometries and the parts of each pair at a glance.

The turning simulation now supports lathe tools with multiple cutting parts.

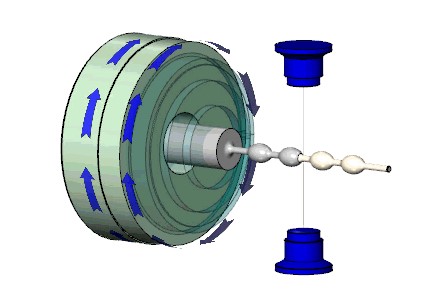

| The new rotary wire EDM feature enables you to cut a fast revolving stock (turning stock) when the wire is locked in the vertical direction. |  Rotary wire EDM Rotary wire EDM |

Turning

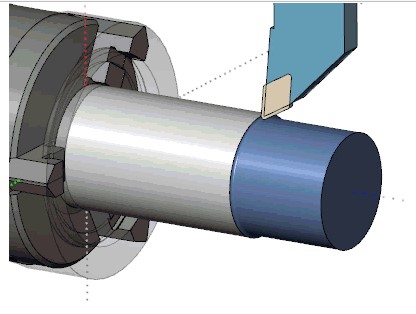

| The new toolpath calculation component for turning applications includes patterns for: • Facing – prepares the high quality base plane on the front surfaces of the work piece. • Roughing – removes excess material on the outer diameter. • Grooving – processes different shapes of grooves on the outer diameter with fast material removal. • Profile finishing – finish the outside diameter by following the input drive curve. • Cut off – final operation to separate the machined part from the stock and to finish the shape of its back face. |

Turning Turning |

Find out more in our videos on our

What’s New YouTube playlist.

The 2016.12 release is now available to all partners from the customer download area at www.ModuleWorks.com. Contact ModuleWorks for further information.