ModuleWorks announces the 2023.12 release of its software components for digital manufacturing. This latest release of the ModuleWorks SDK contains a range of new automation features for efficient toolpath generation. It also comes with the new MDES compliant libraries for system interoperability.

MDESLib - Equipment

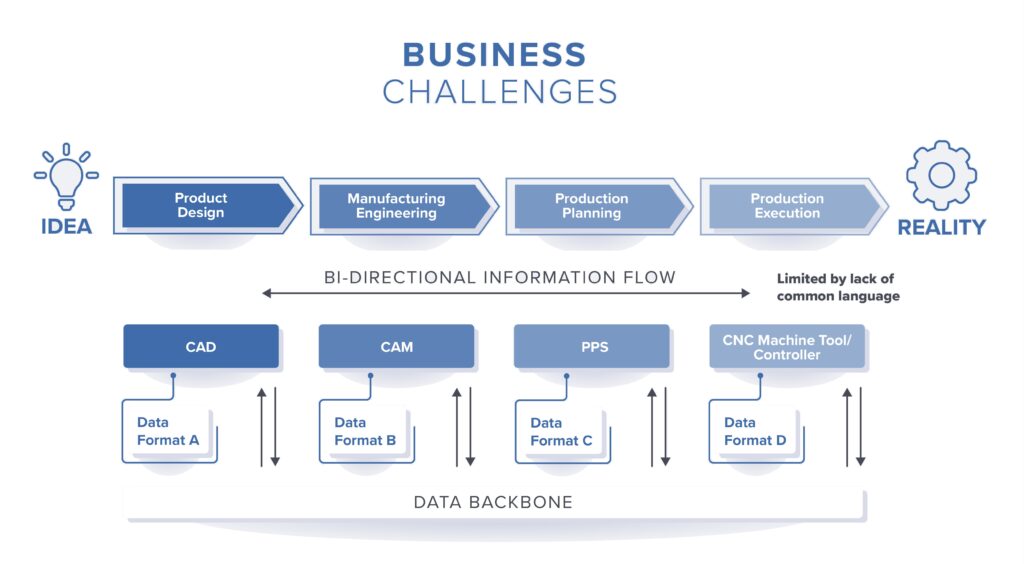

Manufacturing companies use different hardware and software systems that need to exchange data with each other at different stages in the production chain. Since these systems are developed by different suppliers and have different data file formats, there are limits on the information that can be exchanged between these systems.

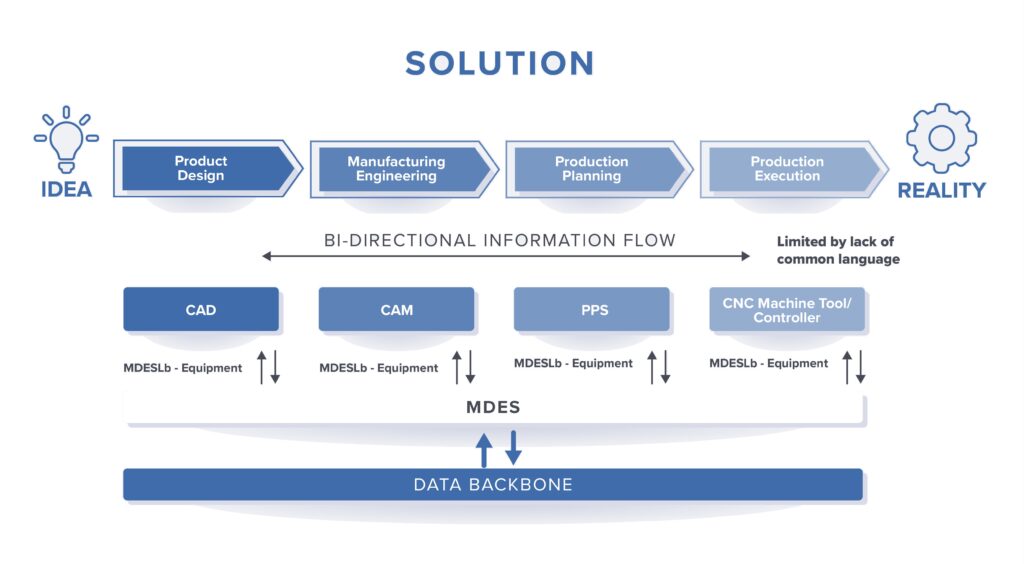

ModuleWorks 2023.12 comes with MDESLib – Equipment, a ready-to-go software library that enables users to efficiently exchange digital representations of manufacturing equipment between different systems using the MDES data specification.

MDESLib – Equipment gives users access to an open and growing ecosystem of hardware & software providers who use the MDES specification. It eliminates the need to build customized data bridges to help companies reduce development and maintenance costs.

Turn-Milling

Radial Cuts

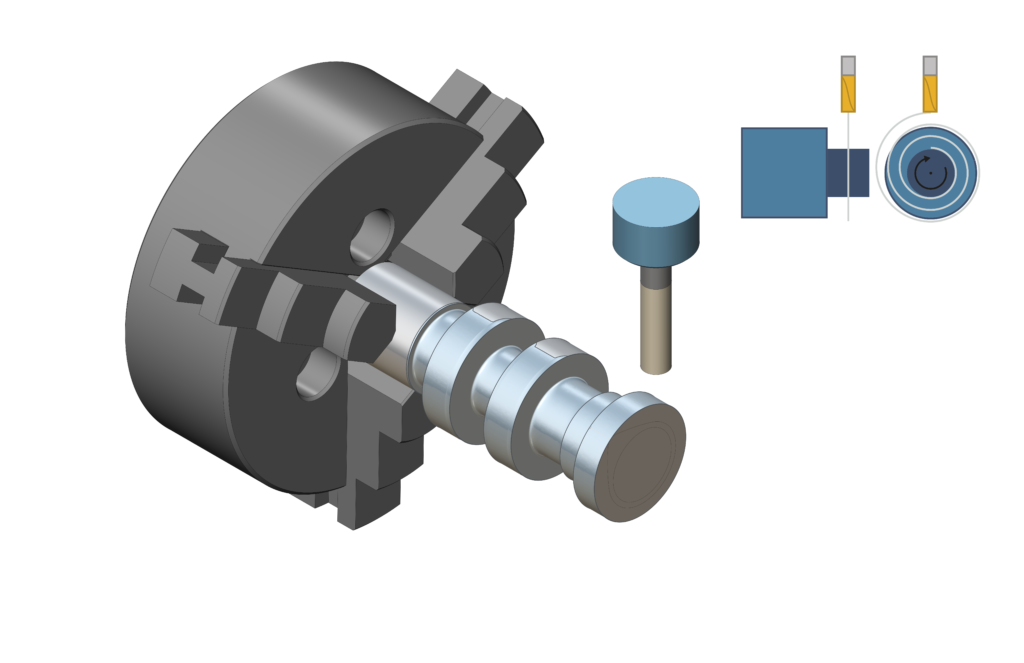

A new cutting pattern for radial cuts improves the efficiency of turn-milling, especially when the diameter is larger than the axial length or when grooves need to be cut.

With the new pattern, the tool ramps down towards the center axis rather than cutting with the side of the tool. This increases machining efficiency by removing the maximum amount of material in the minimum time.

Area Roughing

User-Defined Clearance Surface

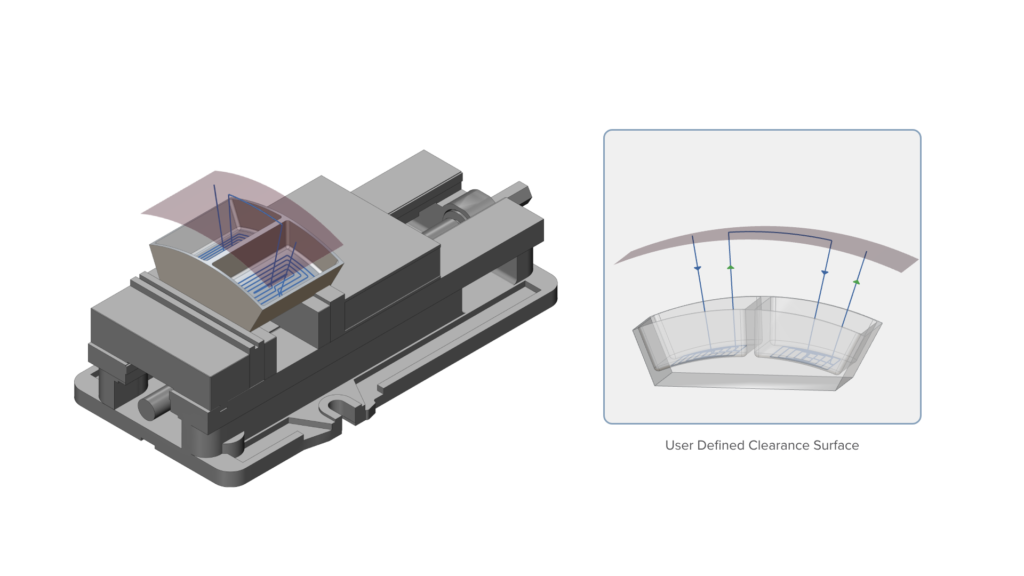

In many machining scenarios it is difficult to safely approach, retract and link a toolpath for complex parts.

A new option for linking the toolpath over a user-defined surface improves machining safety and also allows users to define the clearance surface using geometrical primitives such as planes, cylinders and spheres. As a result, users now have more control over the non-cutting moves for generating safe, collision-free toolpaths during engagement, retraction and linking on complex parts.

3-Axis Machining

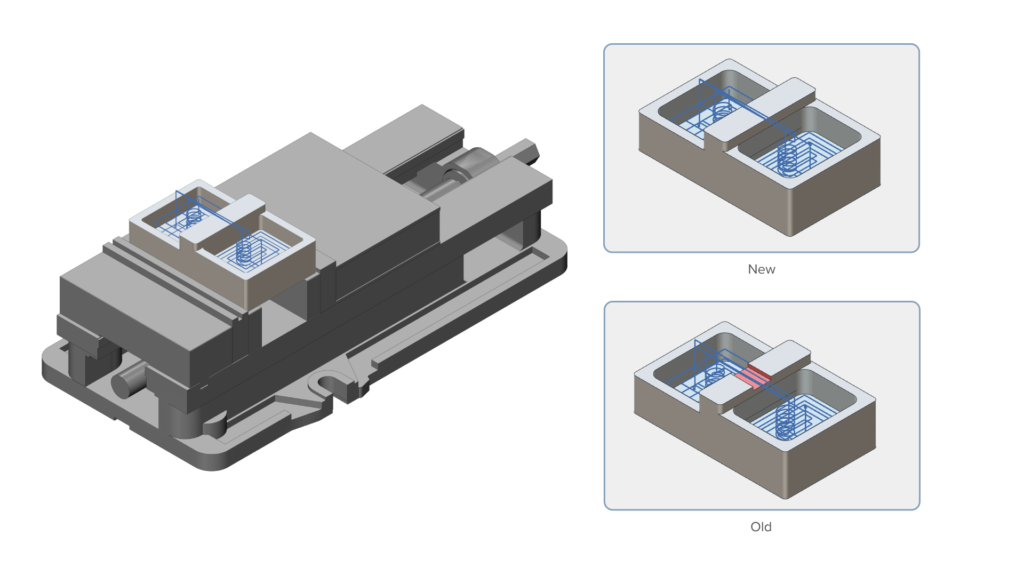

Improved Stock-Aware Linking

ModuleWorks 2023.12 significantly improves linking safety through enhanced stock awareness. In addition to checking the roughing links against the slices and the part, the software now checks roughing links against the in-process stock/workpiece to generate more reliable linking motions that avoid collisions in rapid links and plunges.

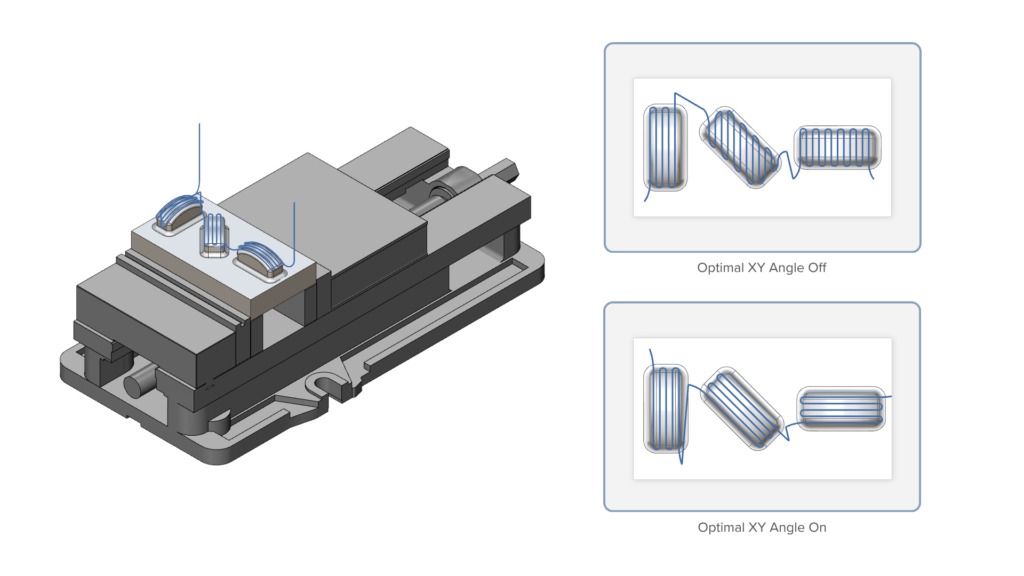

Optimized Cutting Angle

The cutting angle for floor finishing is usually defined by the user. However, when there are multiple faces or containments such as steep, shallow or rest regions, a user-defined cutting angle may not produce the best finishing results.

A new algorithm in ModuleWorks 2023.12 automatically detects the cutting angle based on the longest edge of the face or containment zone. This reduces the overall machining time by optimizing the cutting pattern while improving the material removal rate and the surface finish.

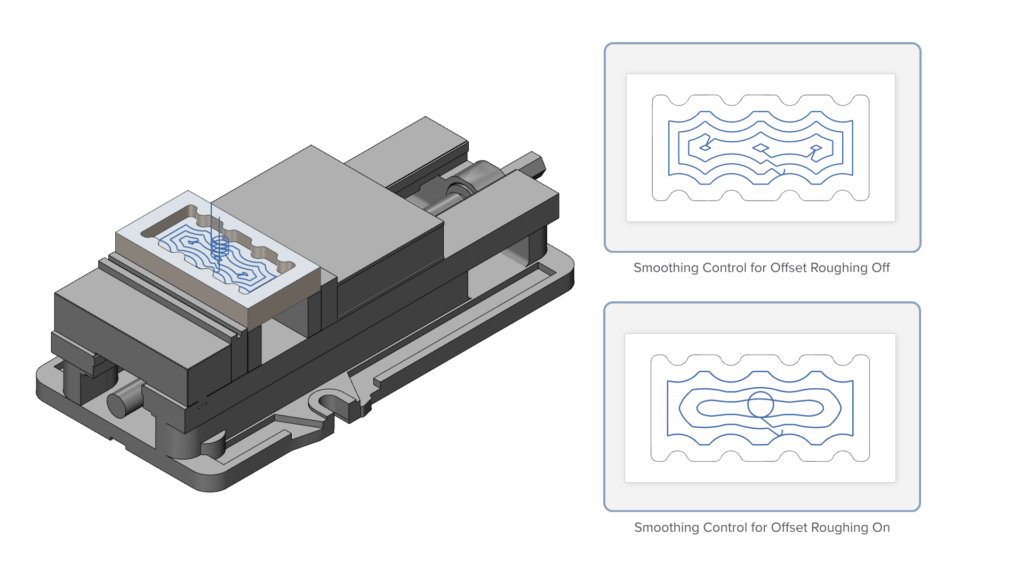

Smoothing Control for Offset Roughing

Toolpaths generated for complex parts with detailed features on the boundaries are often wavy due to offset generation. This wavy toolpath can cause unwanted decelerations and accelerations, resulting in long machining times.

A new option for the roughing cycle smooths out the inner offsets/contours, ensuring the last slice retains the shape of the periphery. The smooth toolpath reduces the fluctuating motions to ensure constant, high-speed roughing and faster overall machining.

ModuleWorks 2023.12 is available for download from the ModuleWorks website.

For more details about these and the other new features and enhancements in the ModuleWorks 2023.12 release,

please see the ModuleWorks YouTube videos.

ModuleWorks is the leading software component provider for the digital manufacturing industry. With over 200 employees and 1500 person-years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life. With its comprehensive portfolio of cutting-edge software components, ModuleWorks enables its customers to optimize their CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness and help them Get There Faster.