Individuality, Innovation and Intelligence

The project AICoM is founded by the Federal Ministry of Education and Research. The project number is 02P20A65.

Details

ModuleWorks and its partners have set out on the project AICoM – Artificial Intelligence Controlled Milling to develop an intelligent machine tool for milling customized workpieces. While the manufacturing industry is growing, market competition, fluctuations in demand, and shortened product life cycles put the industry under pressure. In an effort to ensure competitive advantages for customers, insights of artificial intelligence research and mechanical engineering are united to create a milling machine that outperforms the current industry standards.

Present-day manufacturing is put under pressure by several factors. Mainly, this pressure is caused by industry related factors such as fluctuations in demand and shortened product life cycles and, on a micro-level, the growing requests for customer-specific or increasingly complex products. The need for flexible and dynamic production processes is thus ever present and even expanding. In smaller production batches of complex or expensive products process parameters such as cutting speed are chosen conservatively to avoid damage or economic loss. For many requests, data about the adequate process parameters is not available. More specifically, data about different production batches is lacking, resulting in production that runs below optimal productivity. Learning machine tools could resolve these problems by suggesting optimal parameters for each production batch.

Up until today, machine tools normally receive control commands from number control (NC) programs. In order to handle the manufacturing with complex workpieces in a precise and safe way, Computer-aided Manufacturing (CAM) software is used. However, operating with a CAM system is complex as it requires in-depth knowledge and skills. Furthermore, CAM systems are lacking valuable knowledge about the machine tool, for example about the parameters of the machine, the tool itself, or the setup of the machine. While the information about the machine is theoretically available because the number of sensors within machines is increasing, this information is not optimally used – machine controls are not able to detect or interpret uncertainties that occur during manufacturing. They are even less able to initiate countermeasures against potentially harmful processes. Due to these obstacles, there is a need for intelligent machine tools that are easy to operate on, thereby significantly decreasing the level of knowledge and skill required. Thus, the aim of Artificial Intelligence Controlled Milling (AICoM) is to develop an intelligent machine tool which is able to learn from experience, easy to operate and capable of autonomously planning and executing the production of customized workpieces. To fully utilize the potential of sensors in the machine, data must not merely be collected but also interpreted, allowing the machine to learn. A learning machine tool therefore requires advanced algorithms derived from artificial intelligence. These algorithms subsequently work on two different time frames: one focuses on processes in real time while production takes place. The other one is focused on the past, adding experiences from previous manufacturing processes to avoid past mistakes.

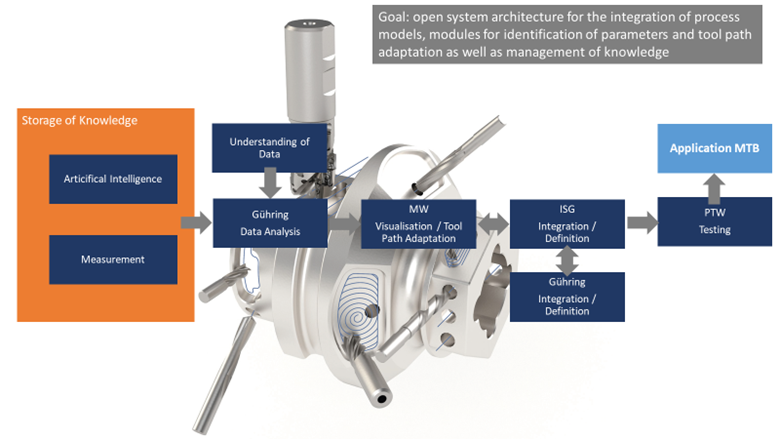

The graphic above shows the incremental goals of the work package ModuleWorks is leading in AICoM and the distribution of contributions to this work package by different partners. With this new approach to production, AICoM might become a beacon in the engineering industry. The machine resulting from this project is significantly easier to operate, more transparent and productive while also having shorter start-up times. It also offers safer and stabler manufacturing processes in conjunction with better product quality. Plus, it is eco-friendly since it is more efficient of resources. ModuleWorks’ specific contributions to the project are the software modules for path planning of production processes and the simulation components for the manufacturing process as well as a full simulation of the machine tool. ModuleWorks and its partners are hoping to build a machine tool that represents the core values of the industry: individuality, innovation and intelligence.