Digital Manufacturing

ModuleWorks Digital Manufacturing optimizes performance and efficiency throughout the CAM and PLM enterprise industries.

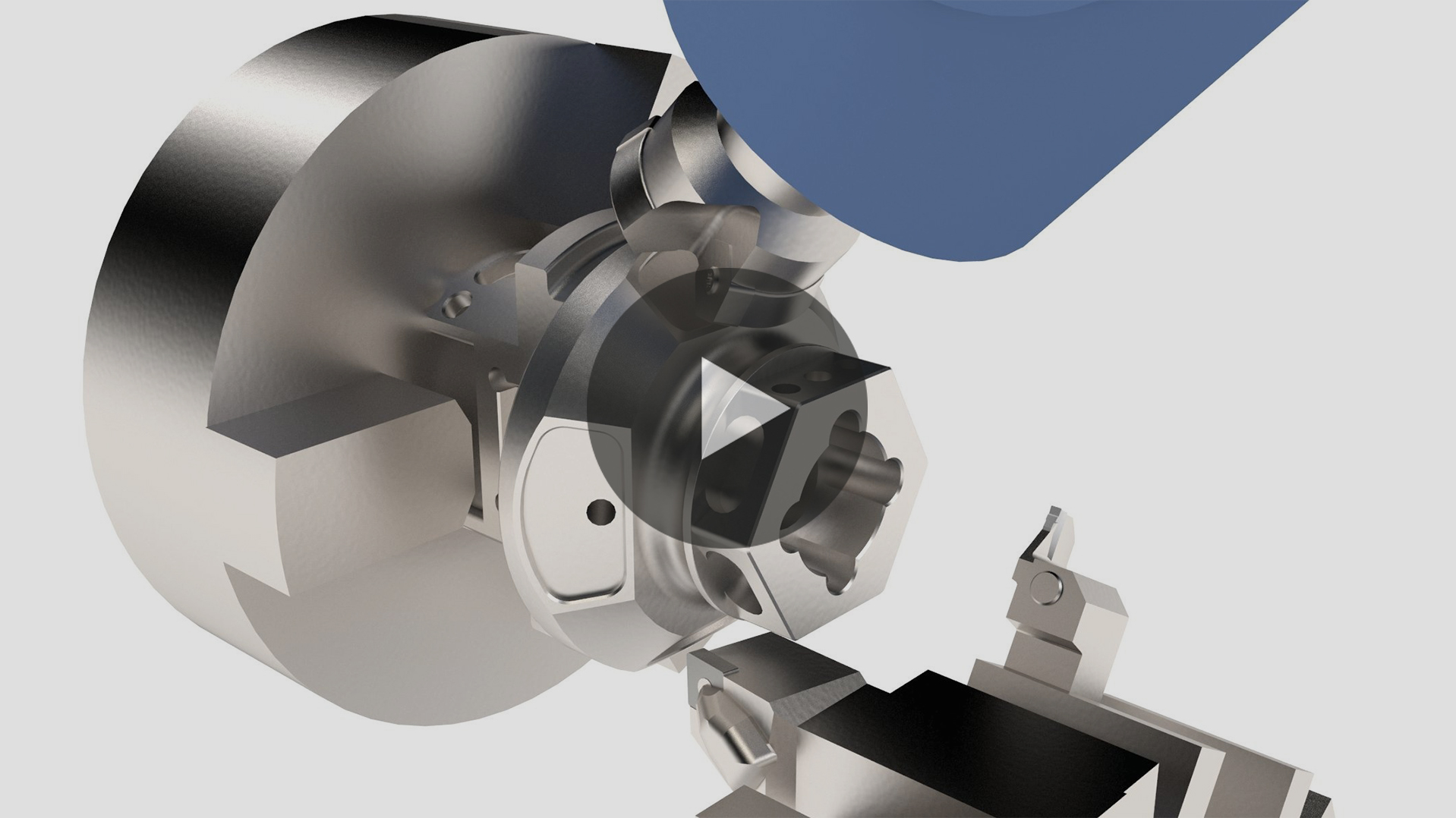

Multi Axis Machining

Automated roughing strategies, easy-to-use indexable processes and full 5-axis simultaneous processes such as SWARF machining build our powerful multi-axis portfolio.

2D Milling

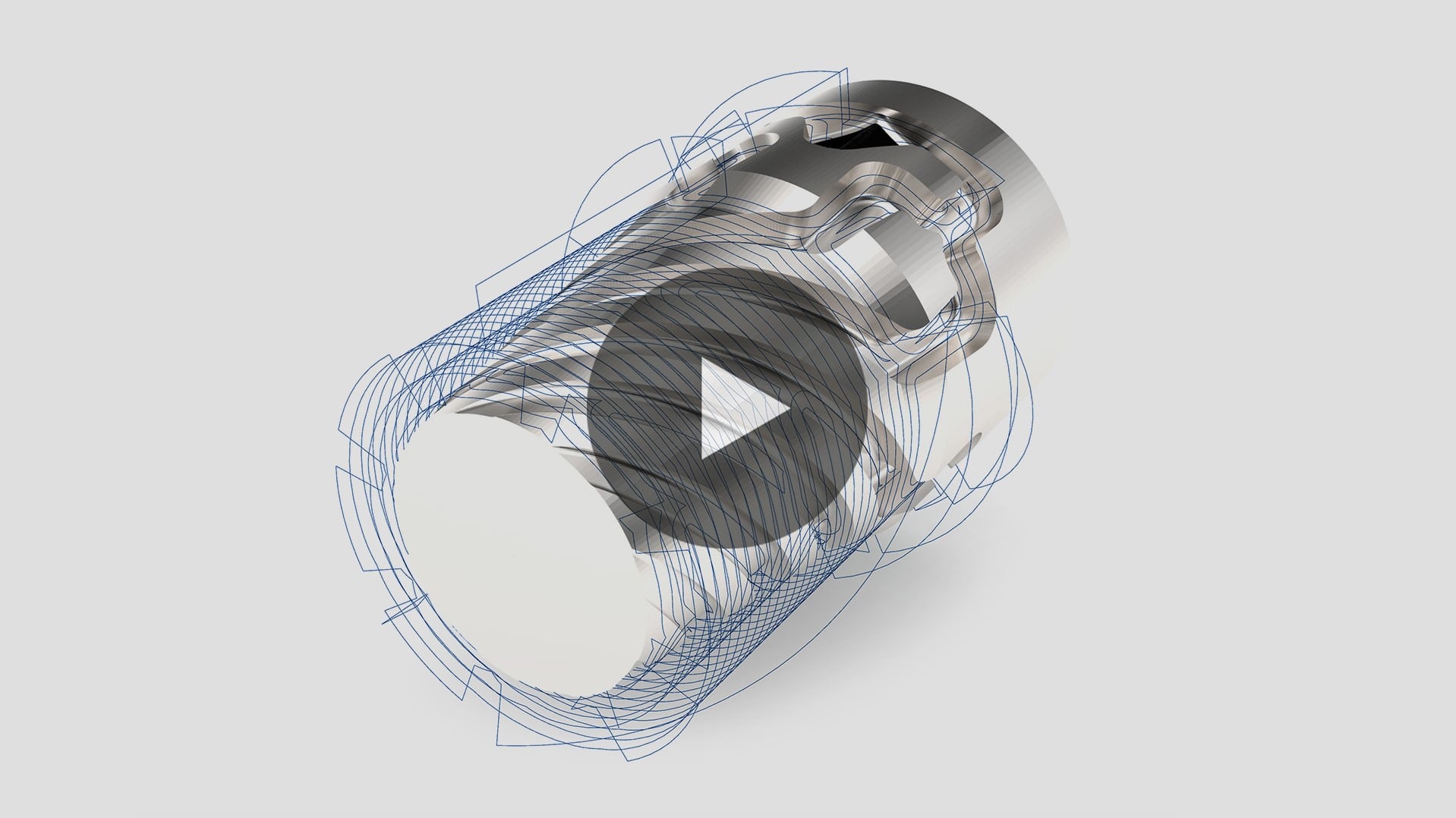

Turning

For machining rotational parts, ModuleWorks provides powerful and easy-to-use toolpaths

for lathes and mill-turn machines. The toolpaths support you with advanced features which can be combined with rotary, 3-axis and 5-axis modules to master any complex operation.

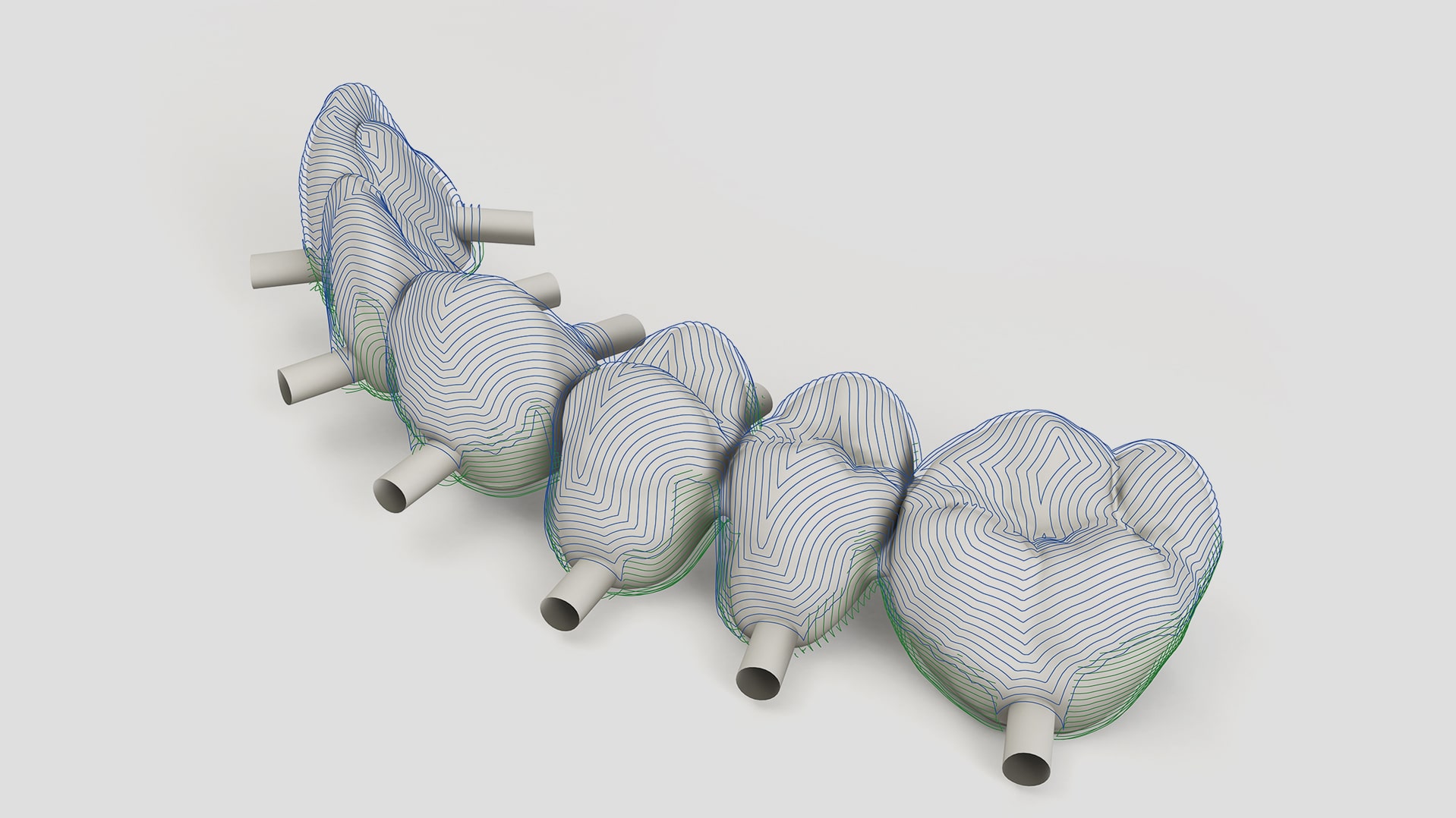

5-Axis Machining

ModuleWorks enables the industry to unleash the full potential of its 5-axis machines. Continuous innovations for our automated indexed processes, e.g. automatic 3+2 axis roughing, and for our automated collision-free tilting strategies are just some of the ways in which we are constantly expanding machining horizons for smoother, robuster and faster machining of mold & die parts.

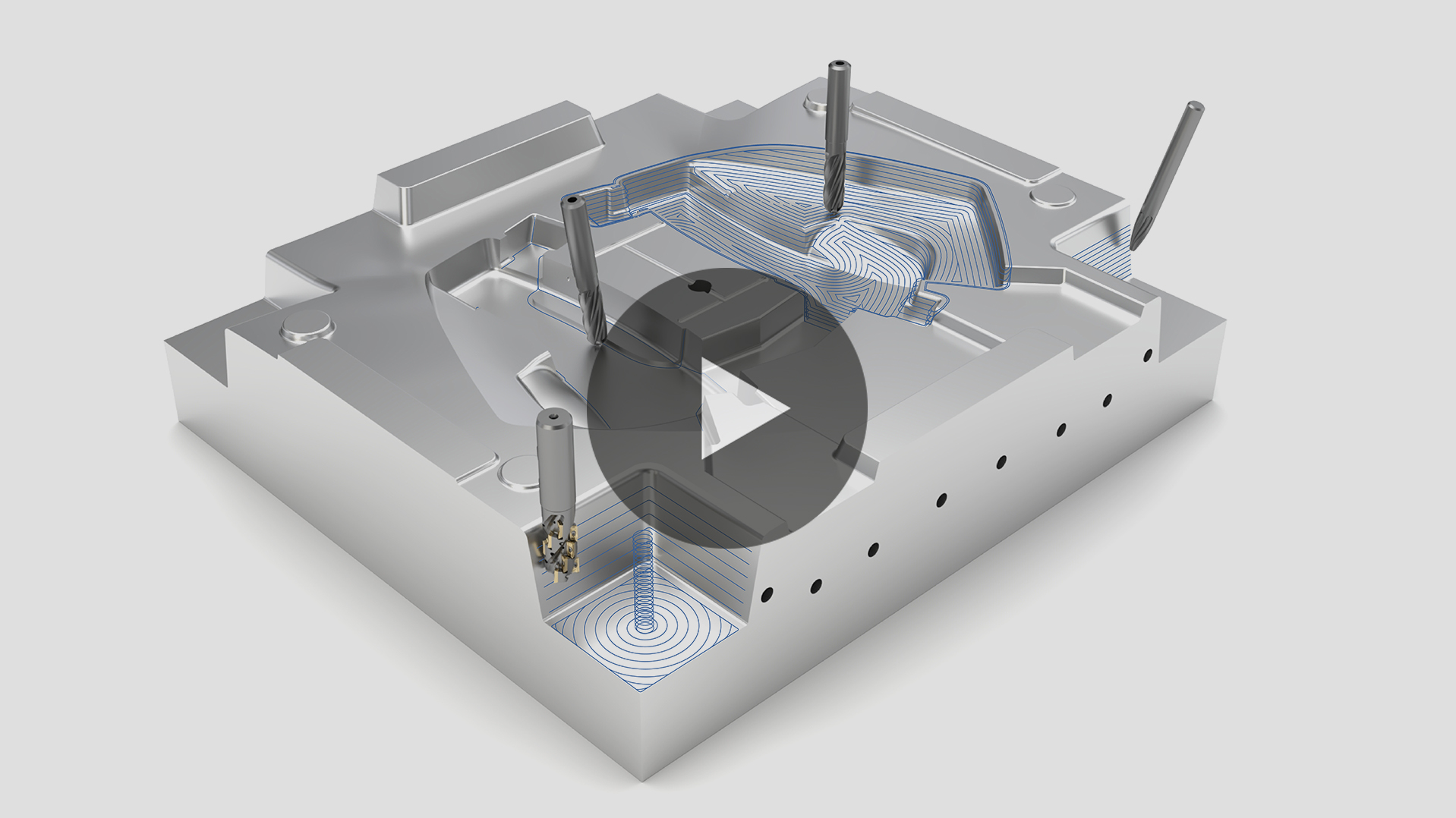

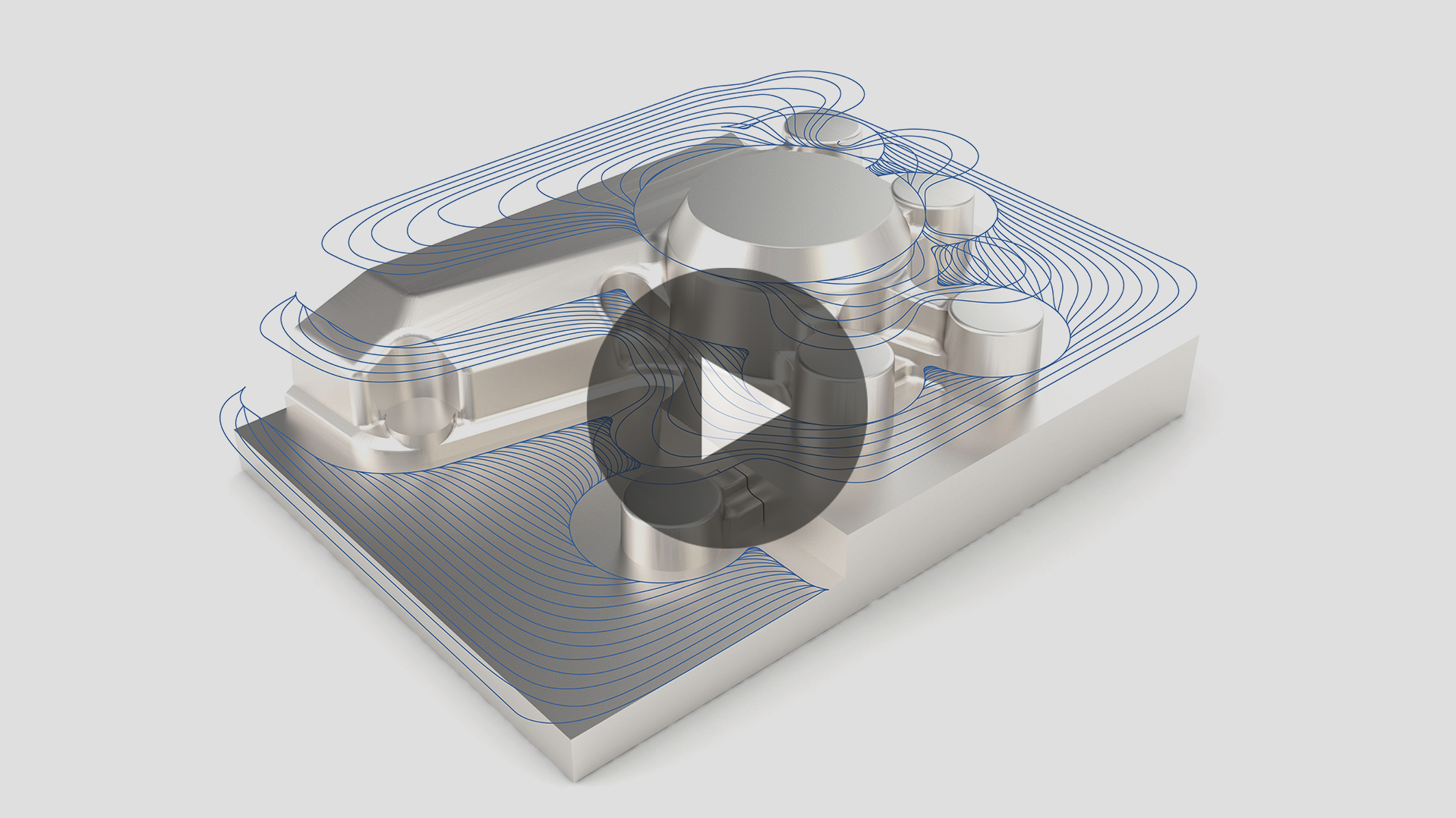

3-Axis Machining

ModuleWorks offers advanced software technology to optimize 3-axis machining, empowering CAM software developers and CNC controller manufacturers with high-performance components for collision-free roughing, rest-roughing, finishing, and rest-finishing. Designed for seamless integration, these components enable rapid, next-level development of innovative 3-axis solutions across a range of industries.

Adaptive Roughing

The adaptive roughing strategy uses the full potential of cutting and machine tools to increase the productivity and profitability of roughing processes.

Our smart toolpath cycles, used in combination with our conventional roughing patterns, increase the value of the whole solution, especially for expensive roughing processes. We apply this technology from 3-axis z-level patterns to 4-axis and full 5-axis roughing as well as turning-cycles.

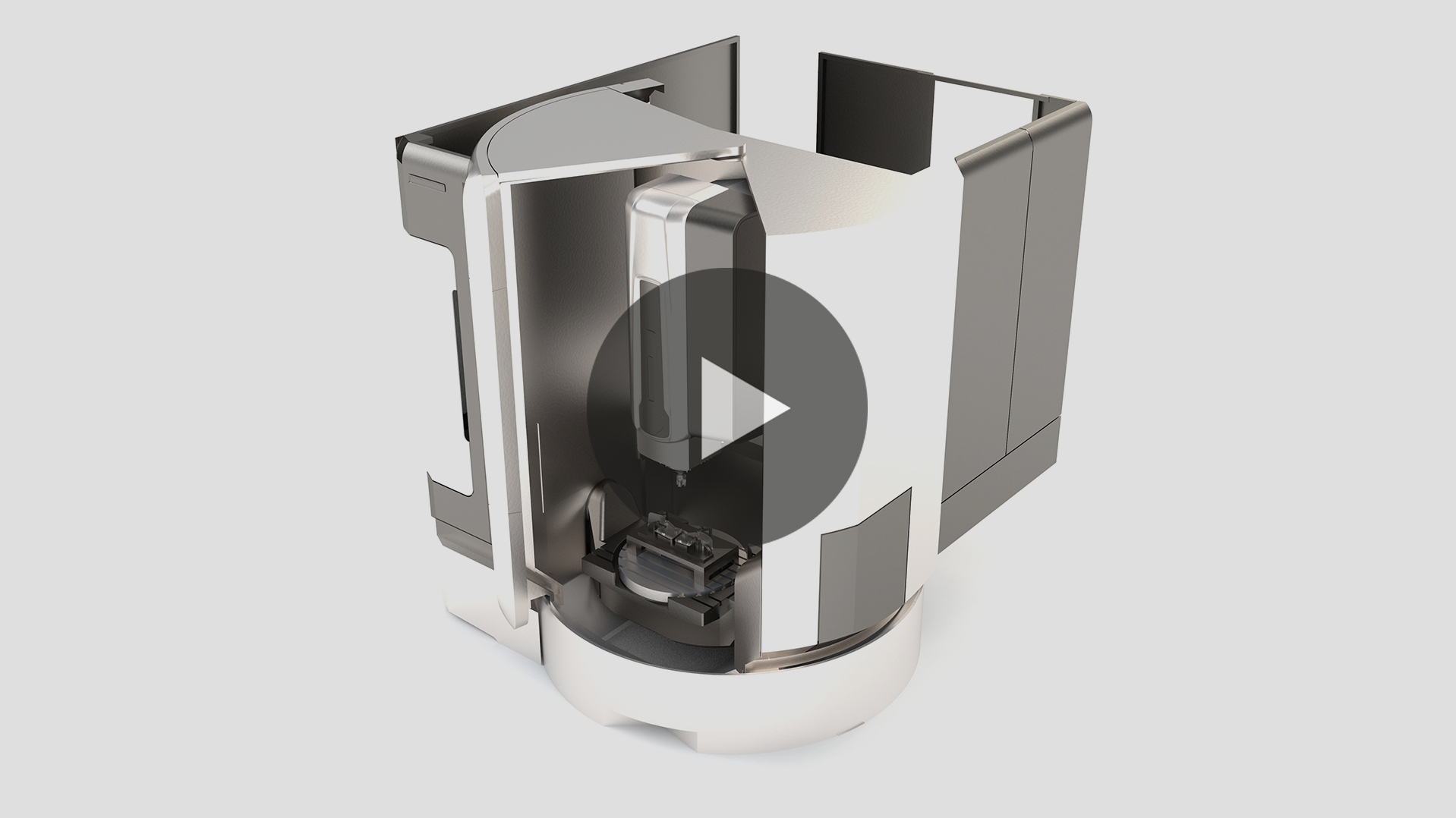

Machine Simulation

Our Machine Simulation optimizes machining safety and profitability from the simple to the most complex machining operations, including 5-axis and combined mill/turn machining. Flexible kinematic definition, powerful APIs and other customization tools let you quickly tailor the simulation to your specific application. Together, we empower your workflows with high-performance machine simulation and toolpath verification tools.

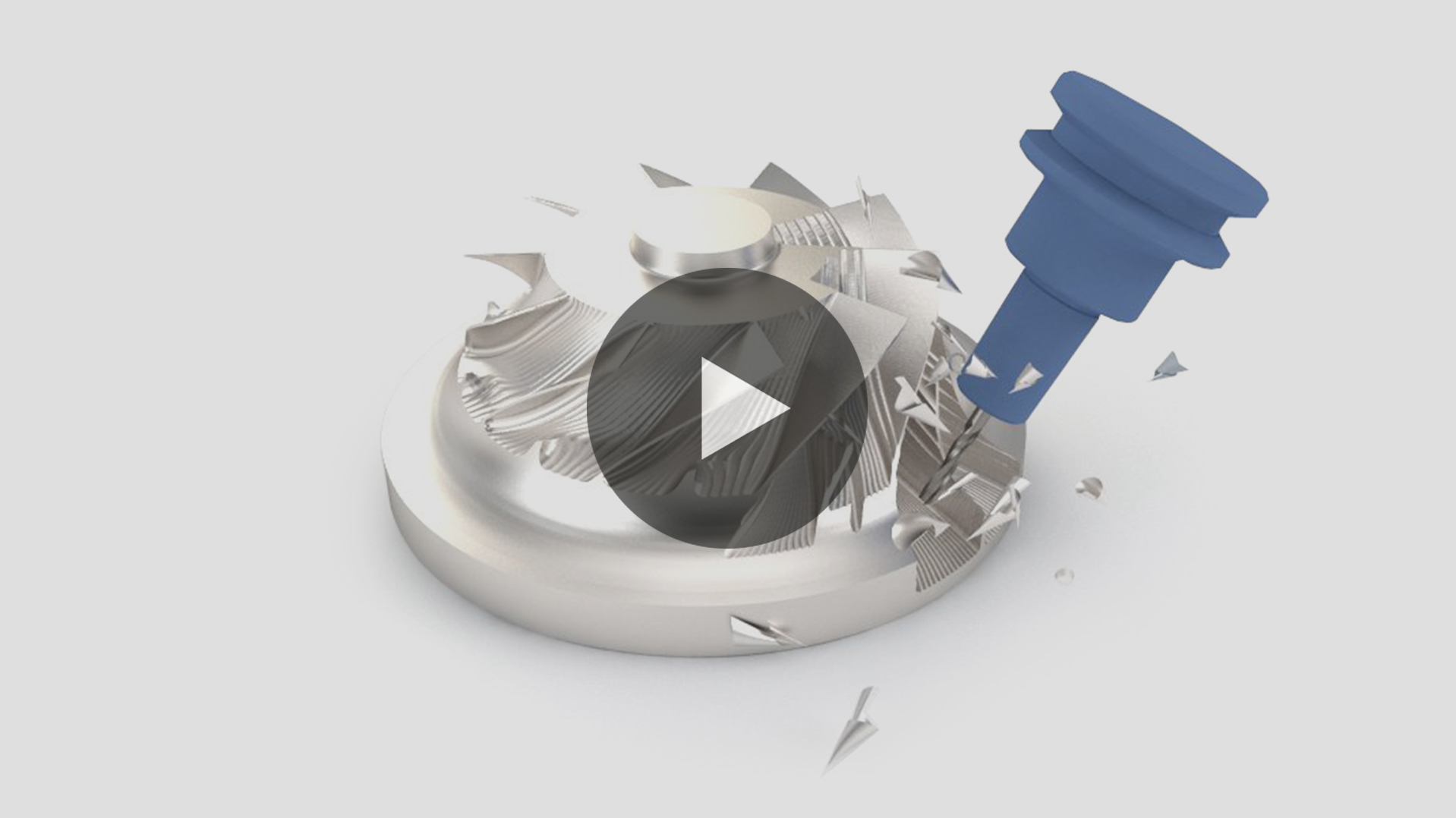

Cutting Simulation

Add value to your application with high-performance digital verification of stock removal and powerful error detection and analysis tools. The adaptive refinement technology gives you a precise definition of the machined component, even on the smallest of features. Animation allows users to preview what will happen on the machine.

NC-Editor

The NC-Editor is a powerful and easy-to-use application for editing, simulating, back plotting and verifying G-code for CNC machining. With an intuitive interface that provides instant 3D simulation while you edit the program, you can detect potential collisions and errors at a glance and quickly optimize the performance and safety of your machining process.

Wood

Our woodworking component provides high-quality 3- to 5-axis toolpath generation strategies and a comprehensive simulation package. Undercut machining is fully supported and powerful finishing cycles speed up your production process.

Support for drill blocks, aggregates, form tools and saw cutting along with advanced algorithms for optimizing

large panel parts deliver cost-effective performance and full application flexibility.

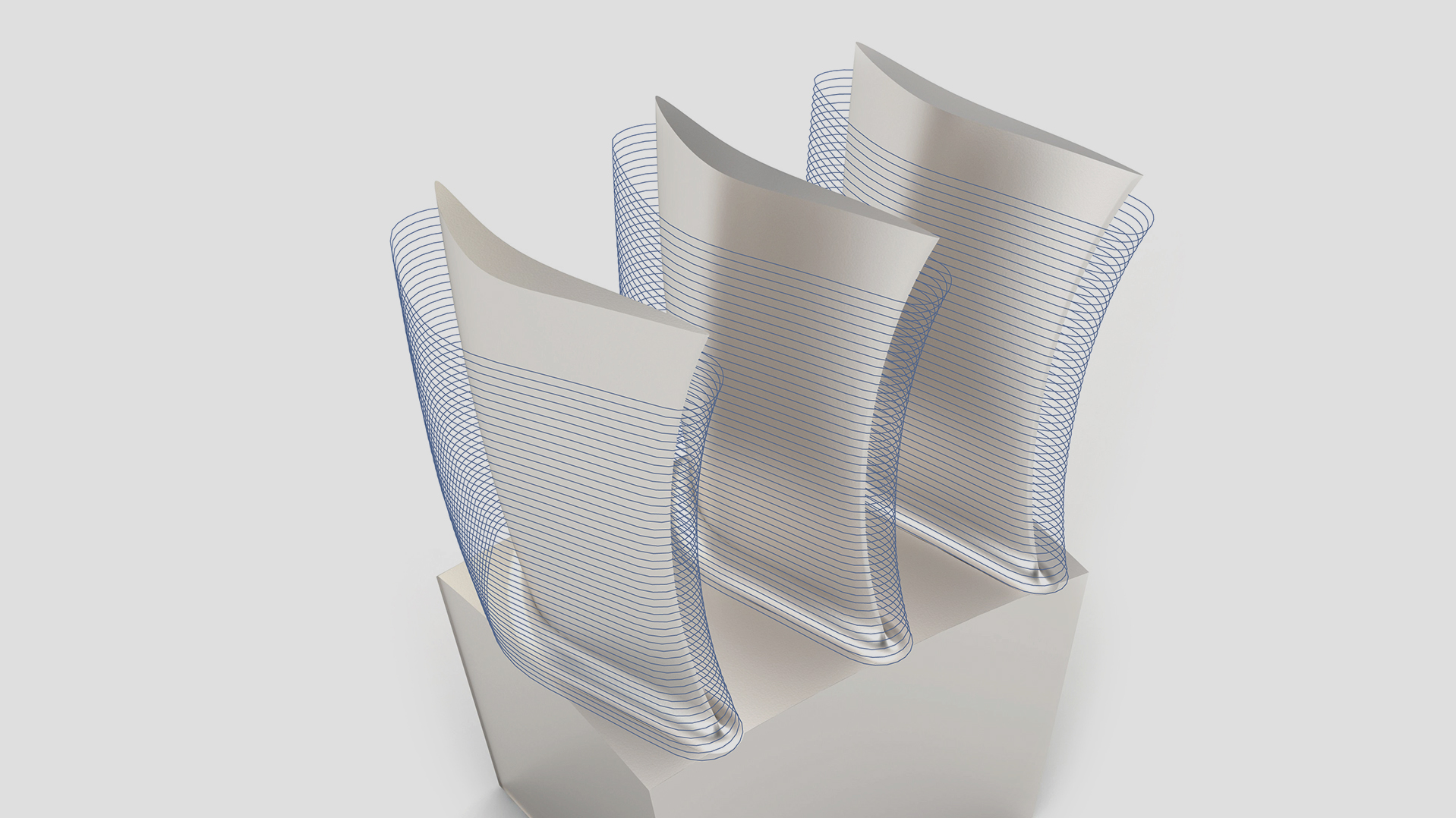

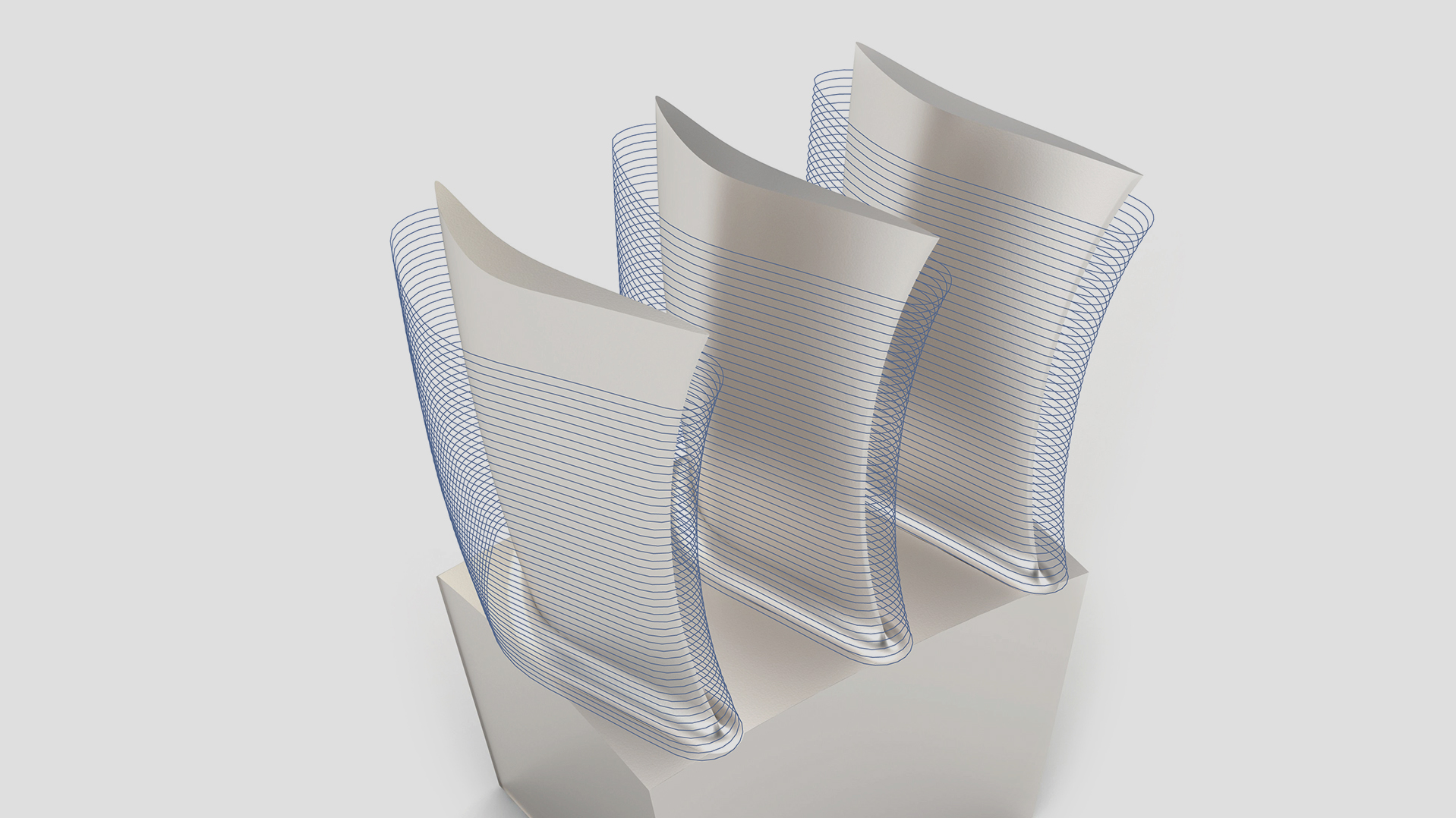

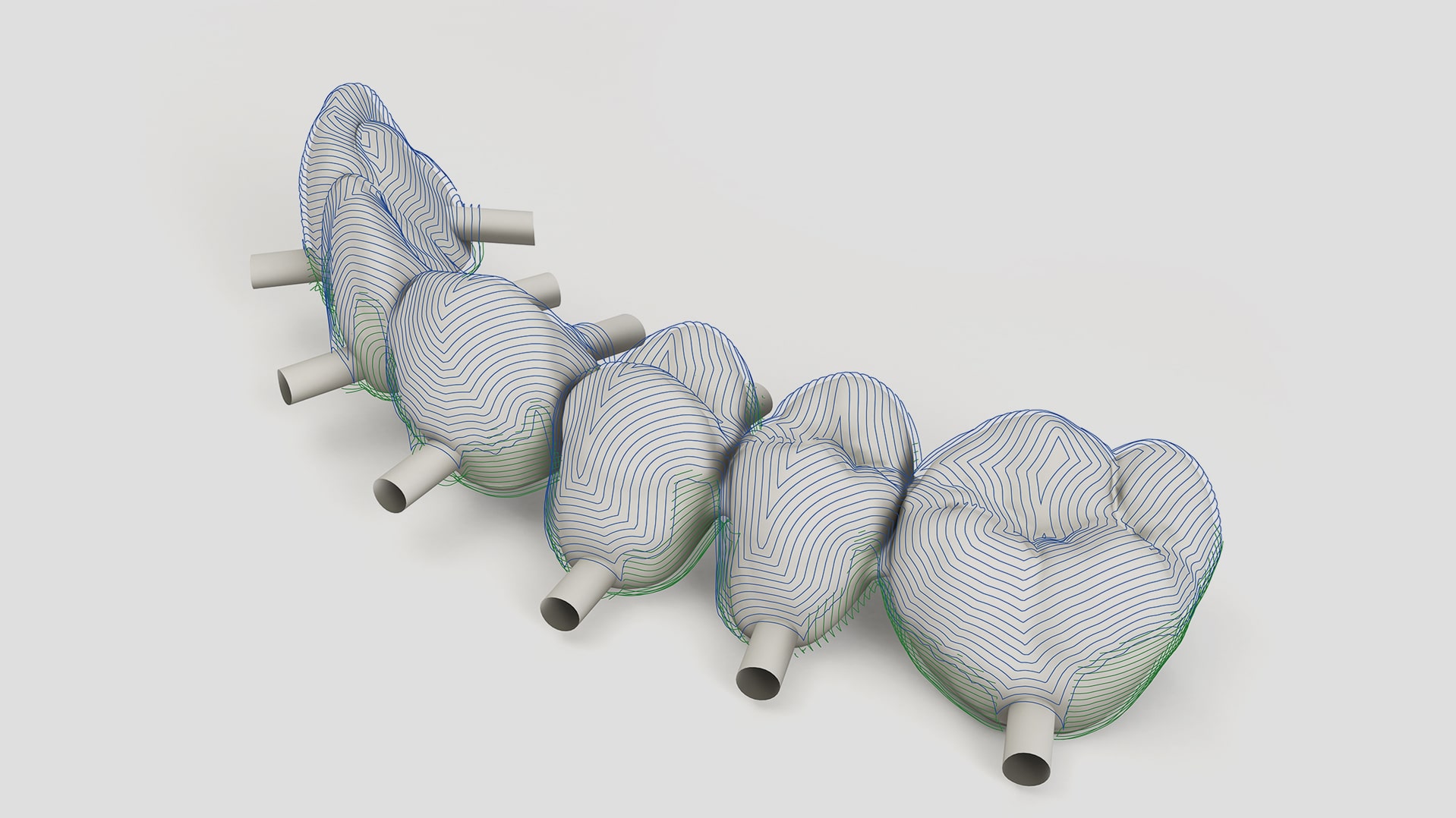

Turbomachinery

With dedicated toolpath strategies, ModuleWorks provides a high-performance turbomachinery solution with an optimized user workflow.

Multiblade parts, such as impellers and bladed disks (so called “blisks“), are very complex and very thin which increases the complexity of the machining process. The multiblade package uses highly optimized and extremely smooth 5-axis toolpath motions to automate the roughing, rest roughing and finishing processes.

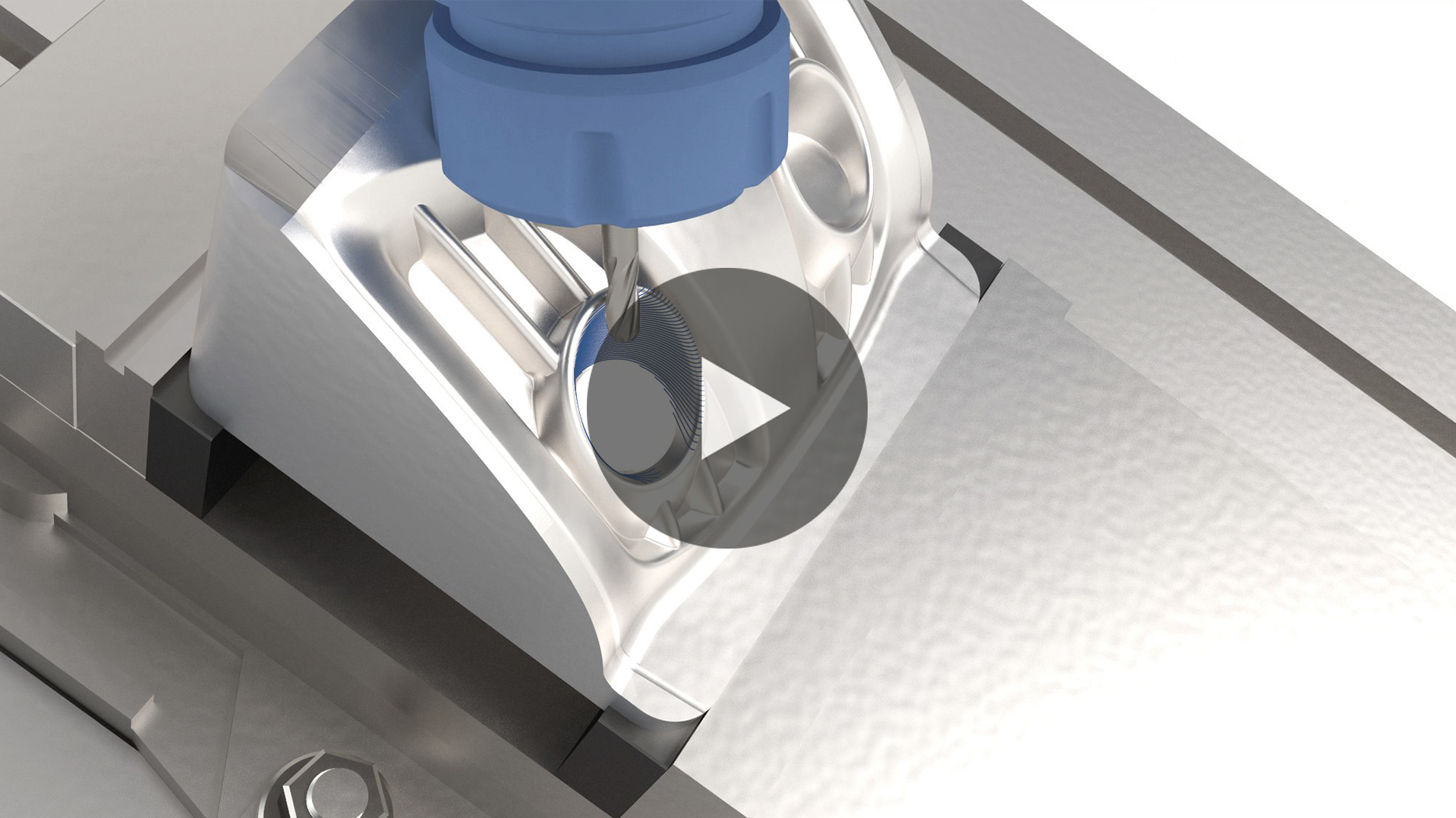

Shop Floor Programming

With NextGen Shop Floor Programming, ModuleWorks offers a completely new user experience for the shop floor environment.

State-to-the-art proven toolpath and simulation technology brings a powerful 3D-based programming solution to the machine operator’s fingertips. Combine the best technology from conversational programming solutions and CAM in one unique solution.

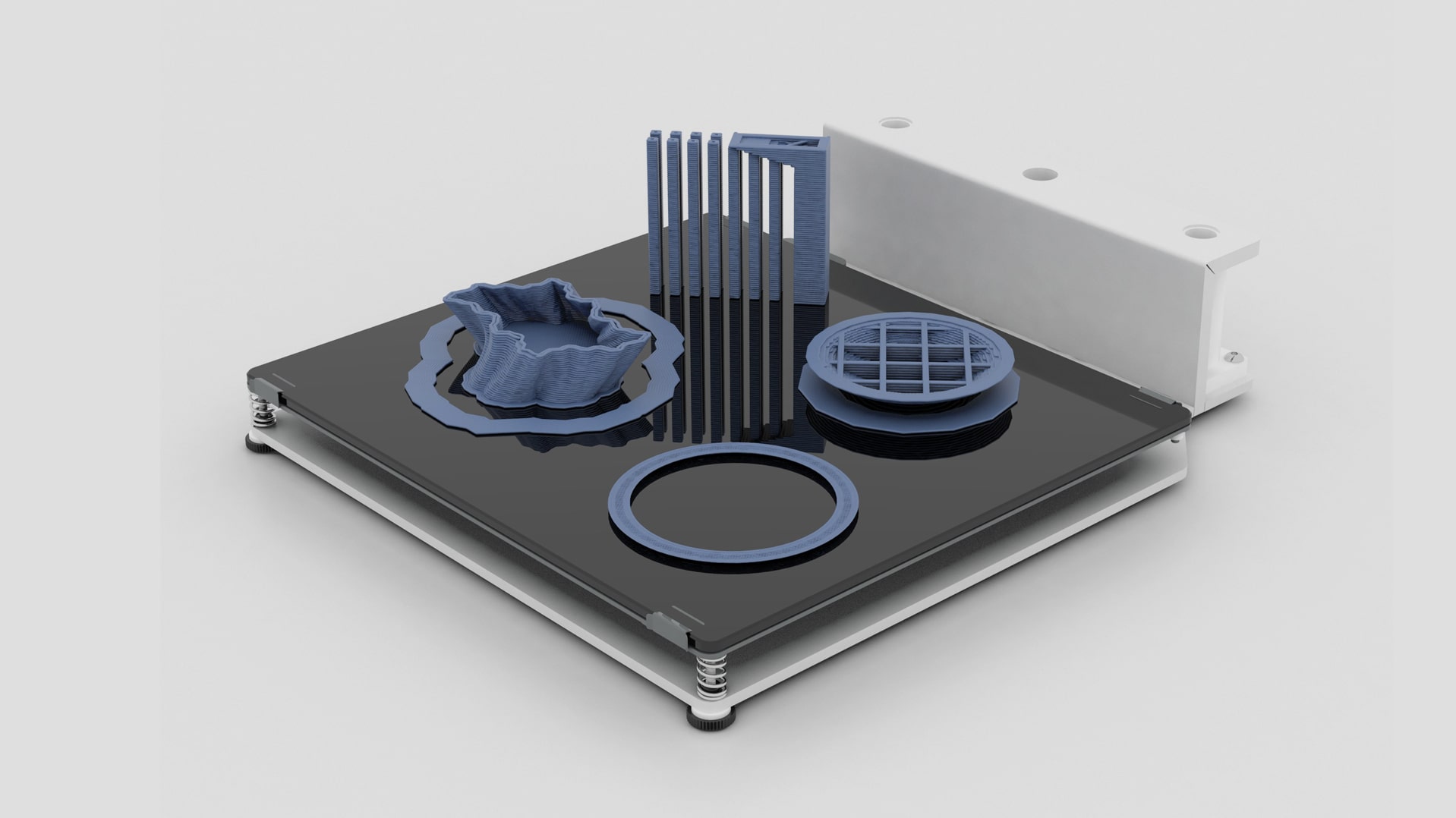

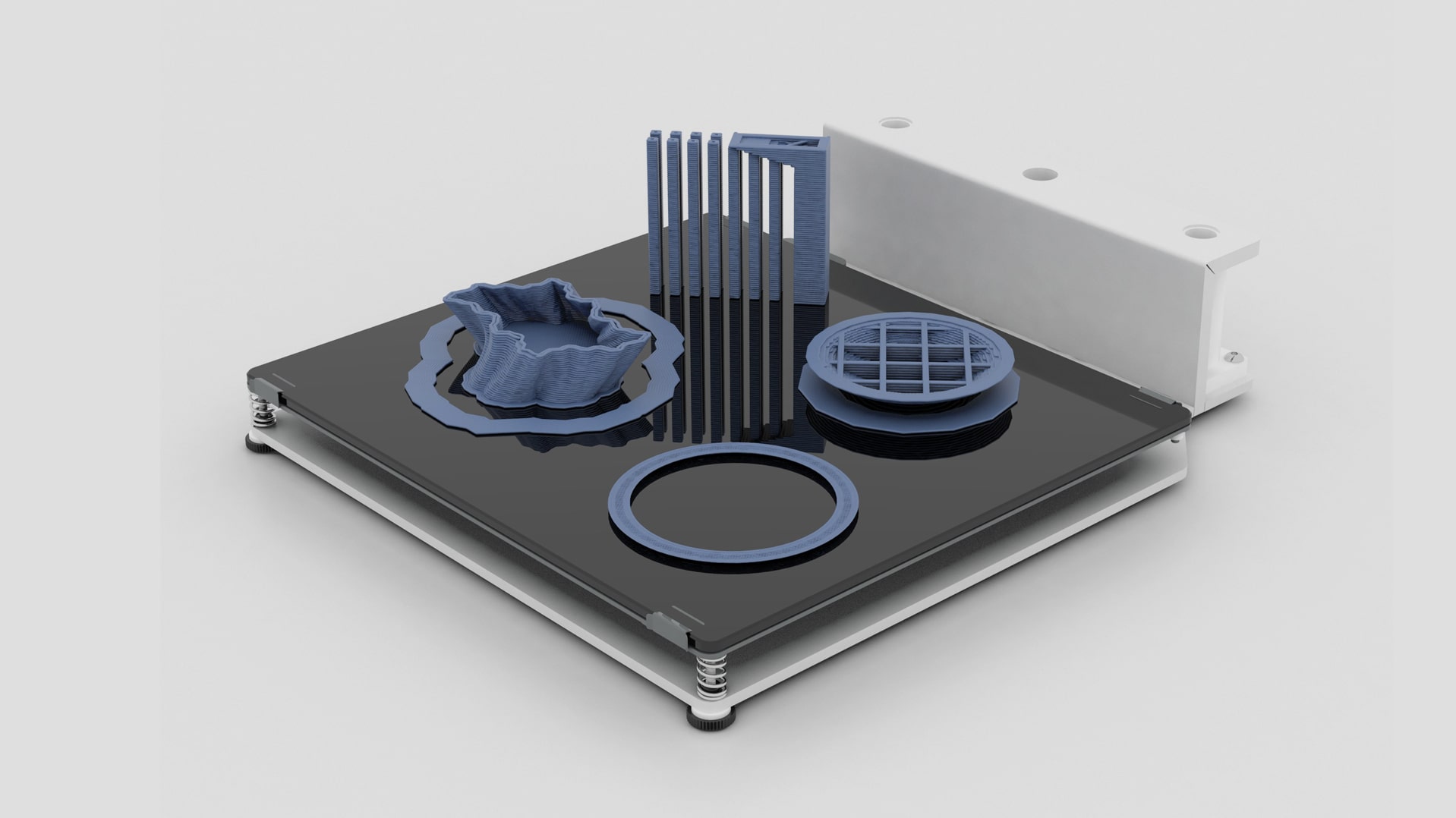

Additive & Process Technologies

ModuleWorks delivers dedicated

software components and solutions for additive manufacturing (SLM, FDM, Hybrid-AM), robotics and ultraprecision manufacturing. Our flexible toolpath generation strategies (from 2D to 6-axis) and full 3D machine simulation software with collision avoidance build a comprehensive portfolio of industry-proven components for fast and cost-effective implementation of process optimizing solutions.

Self-Driving CAM

Equipped with automatic feature recognition and further process automation intelligence, ModuleWorks Self-Driving CAM helps engineers, machine operators and milling centers to dramatically speed up the job preparation process. Automatic selection of geometries and features as well as automatic tool assignment and setup of efficient consecutive operations streamline your job setup and keep your production moving.

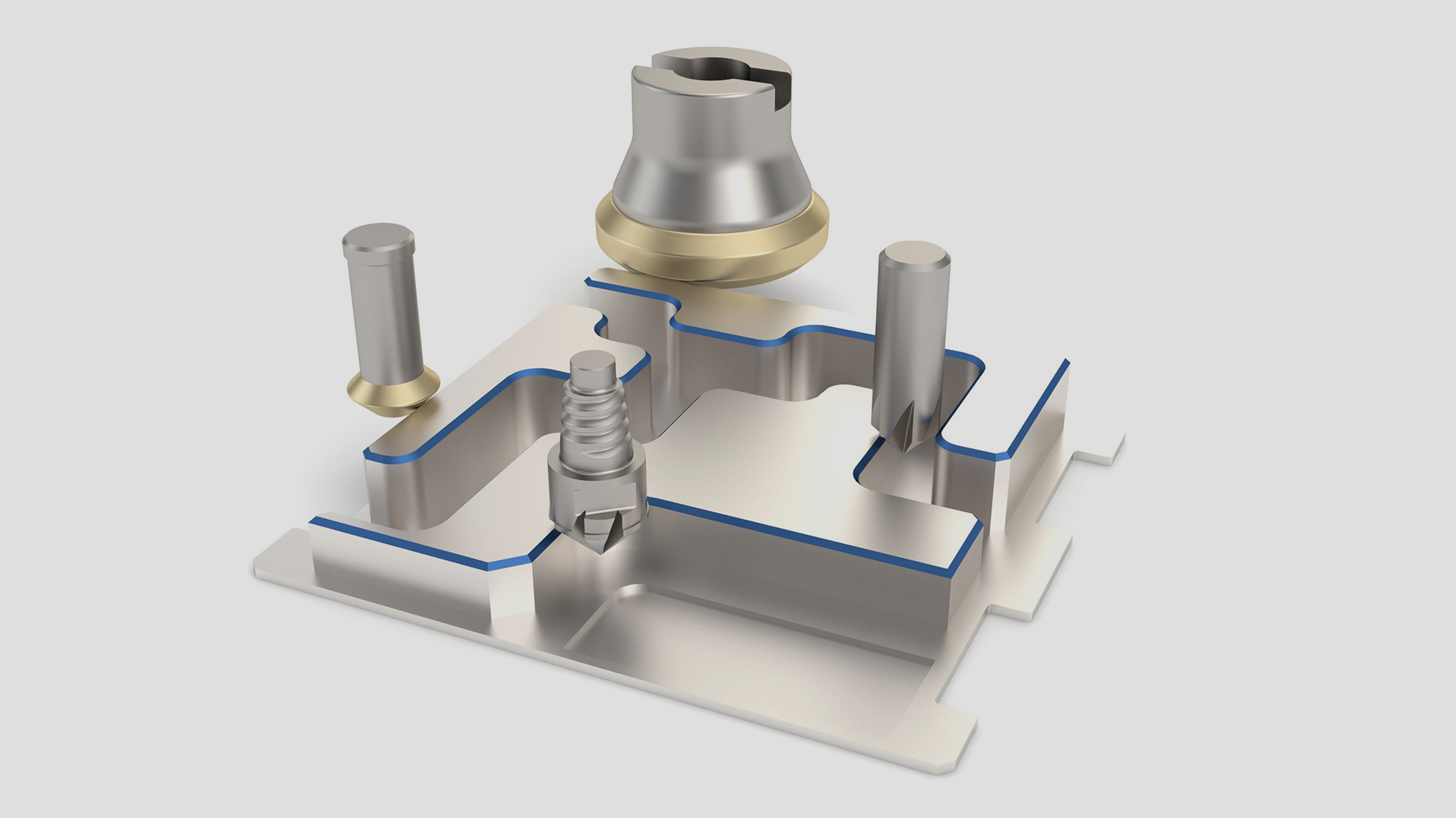

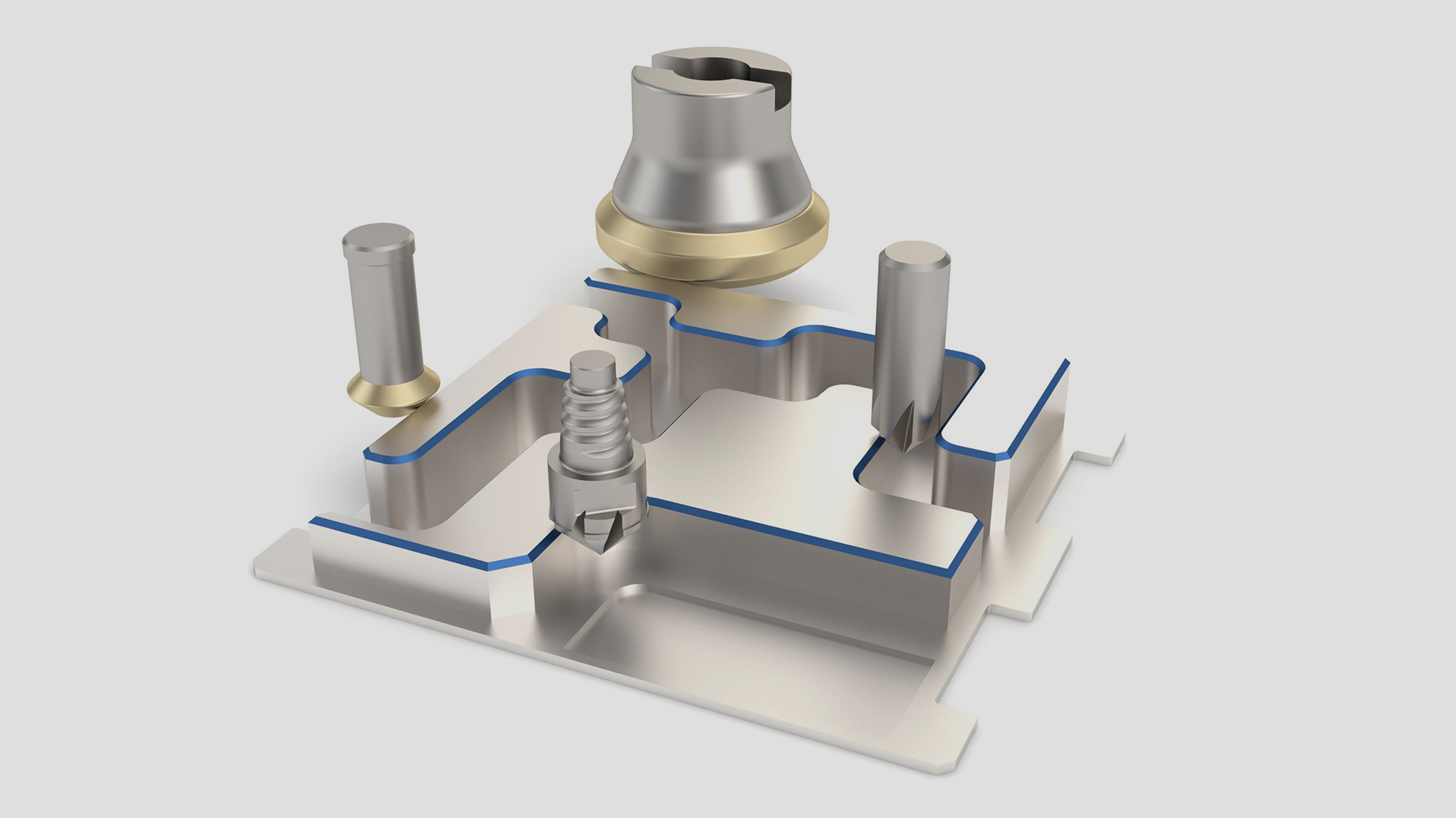

Dental

For dental CNC manufacturers and software integrators, our Dental Framework CAM concept uses fully configurable and verified machining templates for efficient and flexible job implementation. Users can quickly set up and manufacture even the most complex dental designs without any specialist CAM knowledge.

Multi Axis Machining

Automated roughing strategies, easy-to-use indexable processes and full 5-axis simultaneous processes such as SWARF machining build our powerful multi-axis portfolio.

2D Milling

Turning

For machining rotational parts, ModuleWorks provides powerful and easy-to-use toolpaths

for lathes and mill-turn machines. The toolpaths support you with advanced features which can be combined with rotary, 3-axis and 5-axis modules to master any complex operation.

5-Axis Machining

ModuleWorks enables the industry to unleash the full potential of its 5-axis machines. Continuous innovations for our automated indexed processes, e.g. automatic 3+2 axis roughing, and for our automated collision-free tilting strategies are just some of the ways in which we are constantly expanding machining horizons for smoother, robuster and faster machining of mold & die parts.

3-Axis Machining

ModuleWorks offers advanced software technology to optimize 3-axis machining, empowering CAM software developers and CNC controller manufacturers with high-performance components for collision-free roughing, rest-roughing, finishing, and rest-finishing. Designed for seamless integration, these components enable rapid, next-level development of innovative 3-axis solutions across a range of industries.

Adaptive Roughing

The adaptive roughing strategy uses the full potential of cutting and machine tools to increase the productivity and profitability of roughing processes.

Our smart toolpath cycles, used in combination with our conventional roughing patterns, increase the value of the whole solution, especially for expensive roughing processes. We apply this technology from 3-axis z-level patterns to 4-axis and full 5-axis roughing as well as turning-cycles.

Machine Simulation

Our Machine Simulation optimizes machining safety and profitability from the simple to the most complex machining operations, including 5-axis and combined mill/turn machining. Flexible kinematic definition, powerful APIs and other customization tools let you quickly tailor the simulation to your specific application. Together, we empower your workflows with high-performance machine simulation and toolpath verification tools.

Cutting Simulation

Add value to your application with high-performance digital verification of stock removal and powerful error detection and analysis tools. The adaptive refinement technology gives you a precise definition of the machined component, even on the smallest of features. Animation allows users to preview what will happen on the machine.

NC-Editor

The NC-Editor is a powerful and easy-to-use application for editing, simulating, back plotting and verifying G-code for CNC machining. With an intuitive interface that provides instant 3D simulation while you edit the program, you can detect potential collisions and errors at a glance and quickly optimize the performance and safety of your machining process.

Wood

Our woodworking component provides high-quality 3- to 5-axis toolpath generation strategies and a comprehensive simulation package. Undercut machining is fully supported and powerful finishing cycles speed up your production process.

Support for drill blocks, aggregates, form tools and saw cutting along with advanced algorithms for optimizing

large panel parts deliver cost-effective performance and full application flexibility.

Turbomachinery

With dedicated toolpath strategies, ModuleWorks provides a high-performance turbomachinery solution with an optimized user workflow.

Multiblade parts, such as impellers and bladed disks (so called “blisks“), are very complex and very thin which increases the complexity of the machining process. The multiblade package uses highly optimized and extremely smooth 5-axis toolpath motions to automate the roughing, rest roughing and finishing processes.

Shop Floor Programming

With NextGen Shop Floor Programming, ModuleWorks offers a completely new user experience for the shop floor environment.

State-to-the-art proven toolpath and simulation technology brings a powerful 3D-based programming solution to the machine operator’s fingertips. Combine the best technology from conversational programming solutions and CAM in one unique solution.

Additive & Process Technologies

ModuleWorks delivers dedicated

software components and solutions for additive manufacturing (SLM, FDM, Hybrid-AM), robotics and ultraprecision manufacturing. Our flexible toolpath generation strategies (from 2D to 6-axis) and full 3D machine simulation software with collision avoidance build a comprehensive portfolio of industry-proven components for fast and cost-effective implementation of process optimizing solutions.

Self-Driving CAM

Equipped with automatic feature recognition and further process automation intelligence, ModuleWorks Self-Driving CAM helps engineers, machine operators and milling centers to dramatically speed up the job preparation process. Automatic selection of geometries and features as well as automatic tool assignment and setup of efficient consecutive operations streamline your job setup and keep your production moving.

Dental

For dental CNC manufacturers and software integrators, our Dental Framework CAM concept uses fully configurable and verified machining templates for efficient and flexible job implementation. Users can quickly set up and manufacture even the most complex dental designs without any specialist CAM knowledge.

Digital Manufacturing in Numbers

in the manufacturing industry

use ModuleWorks technology

for CAM software development

Your Partner for Success and Innovation

We believe in building long-term partnerships with our clients, working together to achieve shared goals and drive innovation.

Our Experts in Digital Manufacturing

Julia Meyer-Hendricks

Head of Business Development

Digital Manufacturing

Sebastian Wallraff

Head of Technology

Digital Manufacturing

Our mission is to develop leading-edge technology that empowers our partners to turn great ideas into successful, real-world products for the manufacturing markets. Our full range of constantly evolving toolpath calculation and simulation components enable the rapid development of innovative multi-axis CAM solutions for all milling and turning processes. We invest extensively in the continuous development of our technology to spark innovation, increase productivity and help our partners lead the future of manufacturing.