Utilities

Far beyond toolpath calculation and simulation

ModuleWorks offers several utilites to cover a wide range of needs beyond basic toolpath calculation and simulation. ModuleWorks utilities has features for fixing 3D meshes, simulating stock and editing NC code to fill any gaps in automated CAD/CAM processes.

Stock Manager

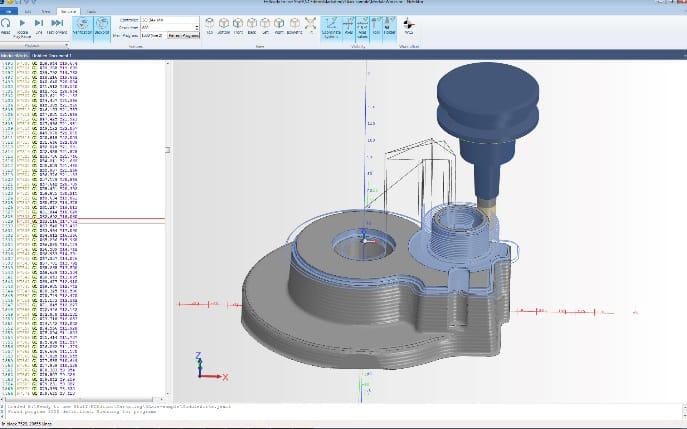

NC Editor

Being able to view and make simple changes to an NC file is very useful on the shop floor. The ModuleWorks NC Editor is a powerful shop floor editing tool that can be easily configured for almost any CNC control.

The color coded textual and graphical view of the NC-code and an NC-code orientated set of navigation and editing features make it easy to validate and fine tune NC programs.

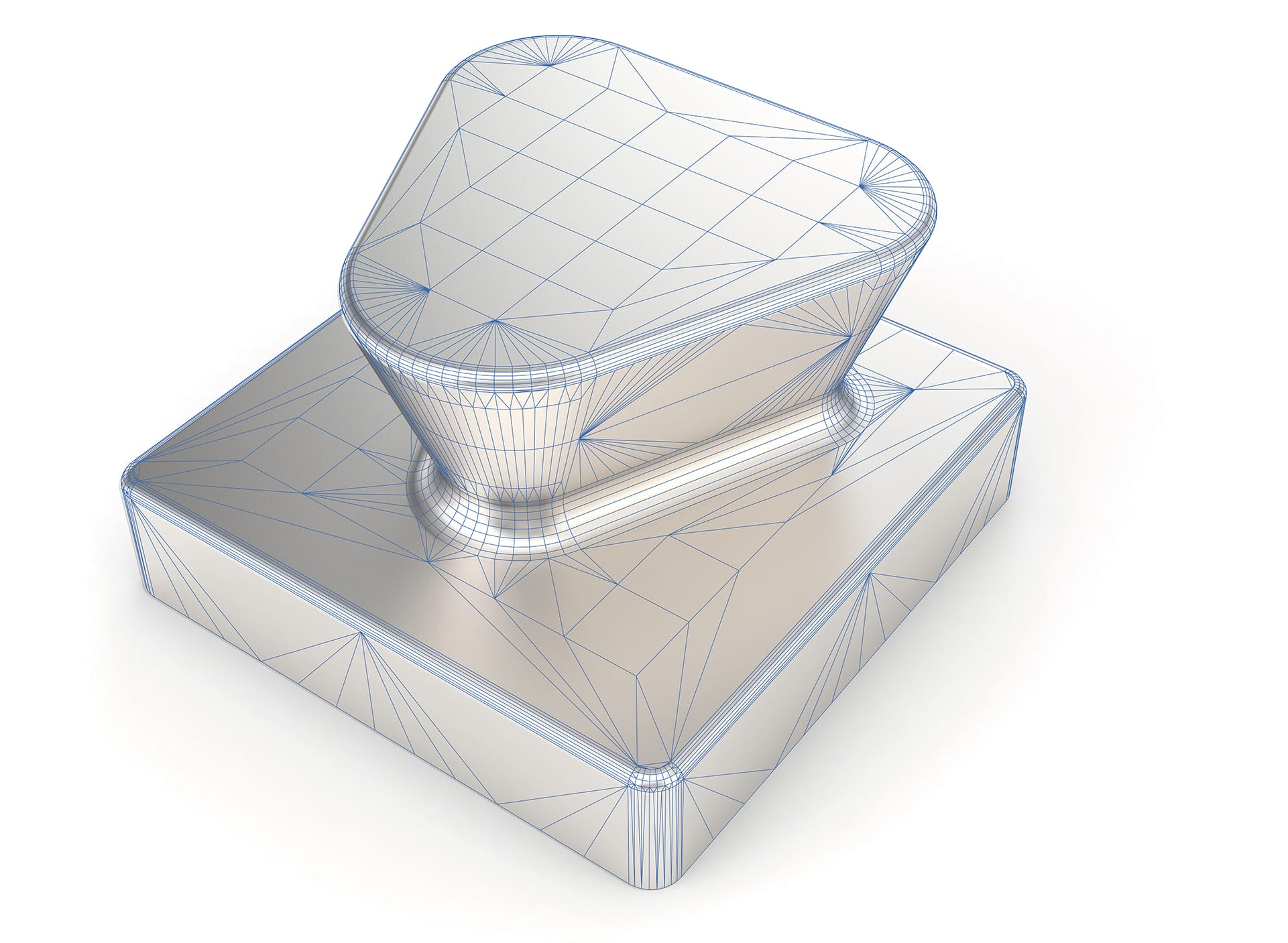

Mesh Toolkit

The Mesh Toolkit is a collection of functions for creating and modifying triangle meshes. Originating from internal use during the development of our own algorithms, we saw the benefits these functions could bring to our customers and decided to condense them into a product.

Several mesh healing, slicing, and generation algorithms are included in this new package. The clean and easy-to-use programming interface lets you get the maximum benefit out of the Mesh Toolkit for your own applications.

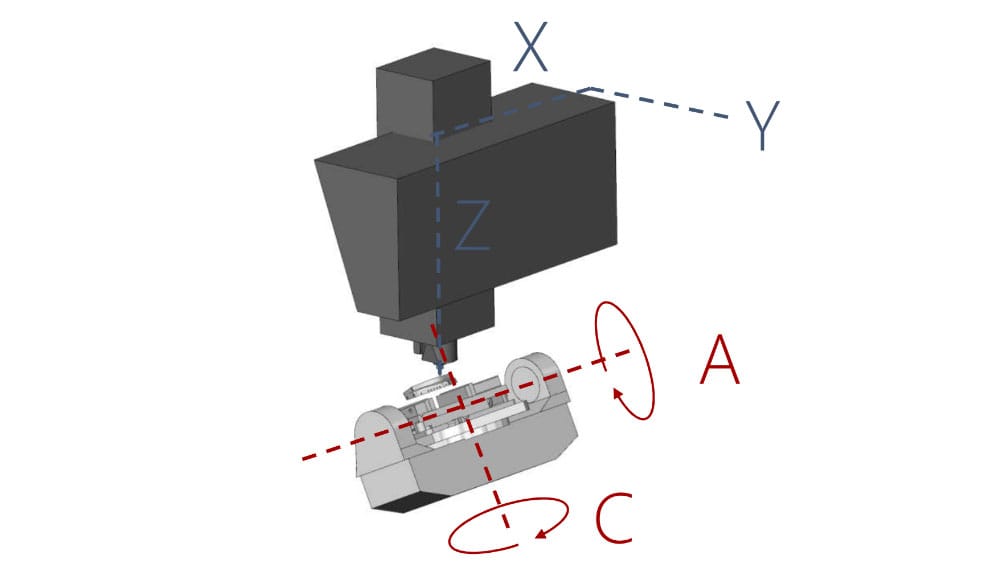

Post Processor Framework

The Post Processor Framework (PPF) lets you script the NC-output for any custom machine tool. PPF uses ModuleWorks MultiXPost as a front-end component to resolve any machine kinematic. Alternatively, you can use the API to integrate the software into your own toolpath environment, independent of the ModuleWorks toolpath calculation.

Let the Numbers Talk

market share worldwide

make us the world market leader in CAM technology.

customers

trust in the quality of our products and value our partnership.

years of ModuleWorks

are just the beginning.

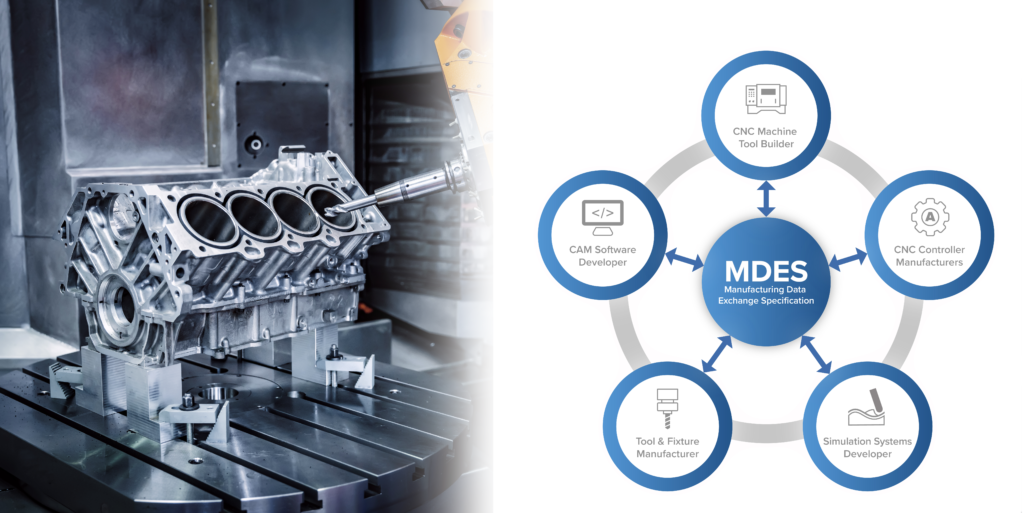

MDESLib - Equipment

To complement the Manufacturing Data Exchange Specification (MDES) with ready-to-go software libraries, ModuleWorks has developed MDESLib – Equipment. These software libraries include basic read/write functionality to use datasets compliant to the specification together with toolpath and simulation components from the ModuleWorks SDK.

The MDESLib – Equipment is addressing organizations building software solutions that must be integrated into the digital thread of manufacturing organizations and suppliers of manufacturing equipment that want to feed the digital representations of their products into the software landscape of manufacturing organizations. This includes organizations such as CAM Software Developers, Simulation Systems Developers, CNC Controller Manufacturers, CNC Machine Tool Builders, Tool & Fixture Manufacturers.