Laser-Aided Manufacturing

Laser aided processes, especially additive processes, will be the foundation of production processes in the future.

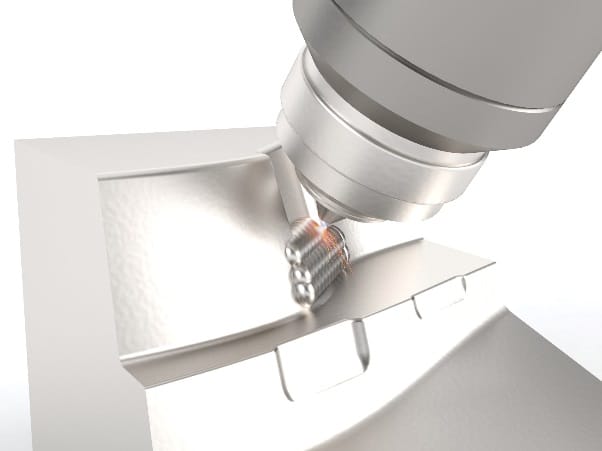

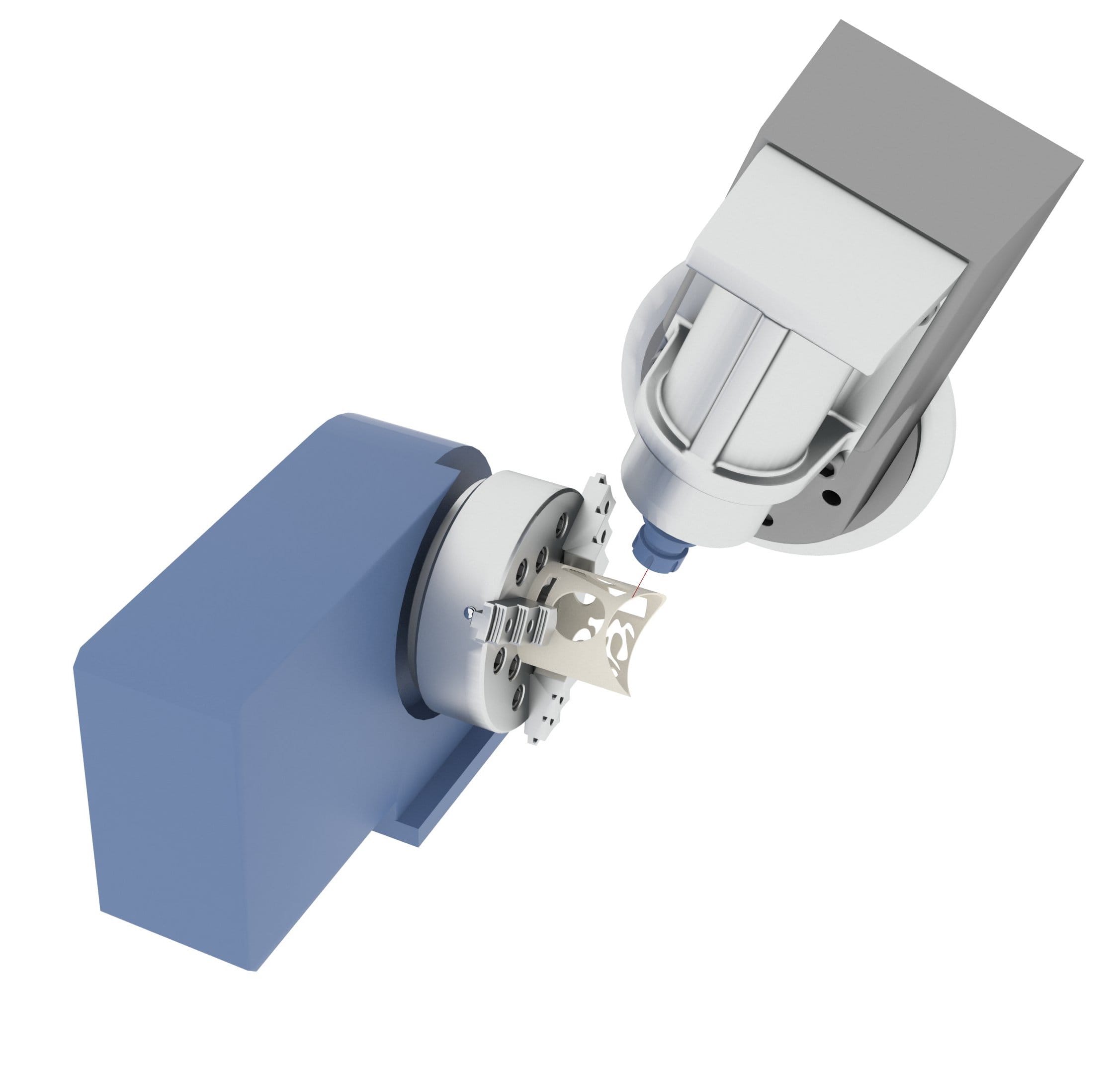

Modern machine tools are able to add material as well as mill the final surface. Defects on expensively produced parts can now be automatically repaired. SLM processes and multi-axis cladding machines are able to produce a larger variety of more complex parts.

ModuleWorks offers an advanced programming environment for laser-aided processes, such as laser cladding, laser cutting and laser hardening. Each process requires its own dedicated set of features. For example, laser cladding requires a constant stepover and a sophisticated layer management system. Laser cutting must handle complex geometrical input, especally in 5-Axis environments. Laser hardening must be able to automatically determine the hardening path on a curved surface. ModuleWorks offers process parameters for each laser aided process as well as geometrical simulation of the laser additive and laser cutting processes, and full collision avoidance with toolpath planning and automatic link motions between operational machining motions.