“May you live in interesting times” is a saying which is commonly used ironically to refer to times of trouble. Well, we certainly seem to be living in interesting times at the moment. At ModuleWorks, we currently have our entire workforce working from home, spread across many different countries. Fortunately, as a relatively agile software company, we are able to transition to home working quickly and easily. We can only begin to imagine the challenges for some industries, such as the manufacturing companies that represent the end users of our software.

Having made the adjustments to enable home working, and maintain a reasonable level of continuity, our thoughts are now turning to the future and what our industry will look like in 3-6 months’ time. In particular, we have been considering our partners and how we can help them to be successful during this time. We expect some of our partners may suffer a financial impact over the next few months but believe it is important to focus on recovering as soon as possible when things return to normal. Of course, ‘normal’ may not be the same normal that we have been used to, so we have been considering what the ‘New Normal’ will look like and how ModuleWorks can help its partners to be ready.

Resources

The next few months will present challenges to many of our partners and some of them may even need to reduce the size of their teams. Indeed, many countries have introduced schemes to help companies do this on a temporary basis, to allow for a rapid recovery. This might lead to a shortage of resources when the demands of the ‘New Normal’ start to appear. ModuleWorks has a large development team, highly skilled in 3D geometry and CAD/CAM algorithms, and modern, agile development processes ideally suited to project work. As new demands start to appear, ModuleWorks is happy to discuss any requirements, either large or small, to help its partners build solid foundations for the future. Click here if you would like to know more or click here to join our Digital Manufacturing Newsletter.

Digital Twin

Travel is currently severely restricted, and it is likely that some level of restrictions will continue for most of this year. This presents a range of challenges, especially for hardware companies such as machine tool builders. At the time of writing, it is not clear which major exhibitions are likely to go ahead, and so presenting physical machines to potential prospects is difficult

For some time, ModuleWorks has provided technology to support the Digital Twin initiative of Industry 4.0, and this year launched a new product – Visual Twin – to provide the most realistic virtual equivalent of a machine tool. To show you what the Visual Twin can do, we’ve planned a dedicated webinar. Click here to sign up for our Digital Factory Newsletter and get all the information on the Visual Twin webinar.

Automation

As the manufacturing industry returns to work, it is likely that some countries may impose social distancing constraints, such as the 2m rule. This may require some companies to reduce the number of people on the shop floor or in some offices. One way to enable a reduction in the number of people is to increase the level of automation. This has already been the trend for many years and it is likely to accelerate as we return to the ’New Normal’.

Also, given the international supply chain challenges over the last few months, some industries will look to establish more local suppliers. As these suppliers may well be in higher cost countries, it will be important to have a high level of automation to keep costs at an acceptable level.

ModuleWorks provides a framework to enable automation. Join our webinar to discover what it can do for your business. Click here to sign up for our CAM Automation Newsletter to get further information on the webinar including the registration link.

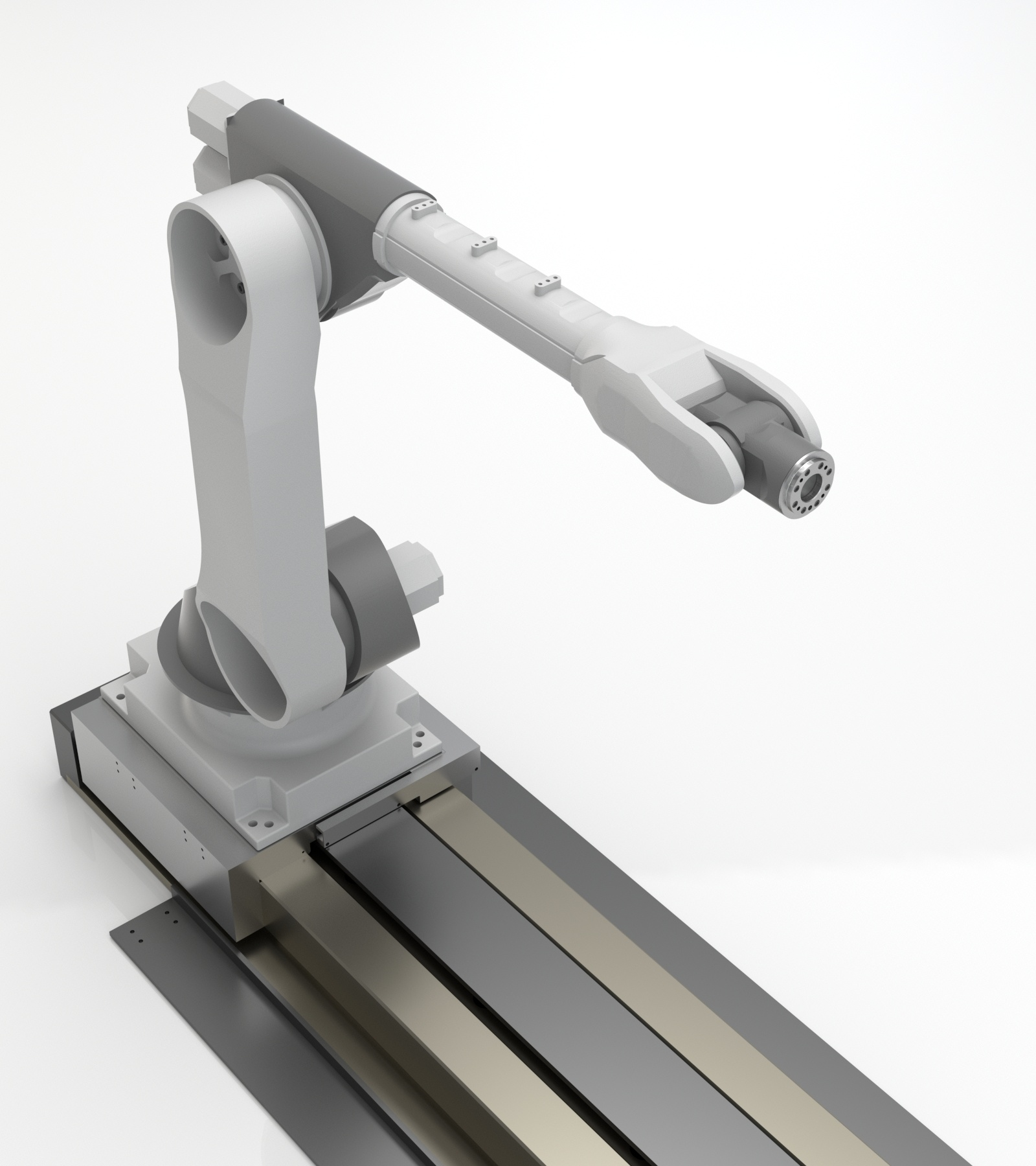

Robotics

Another trend which is likely to accelerate in the ‘New Normal’ world is the use of robots. The demands of social distancing and cost control are likely to increase the use of robots in the manufacturing industry. In particular, the development of cobots, designed to work alongside people, could prove to be a significant step towards this.

We’re planning a webinar during late summer to provide information on our developments in robotics and additive manufacturing. If you would like to be informed about this webinar, please click here to register for our Additive Newsletter.

The success of ModuleWorks depends on the success of our partners. We want to do everything we can to support our partners to get through this difficult time in a way that allows them to thrive in the ‘New Normal’ world. We are looking forward to seeing an initial decrease in the number of infections and hope things get back to “normal” as soon as the situation allows.

ModuleWorks is the leading software component provider for the digital manufacturing industry. With over 200 employees and 900 man years of software development, ModuleWorks’ expertise in toolpath creation and simulation is recognized throughout the industry and its software components are already optimizing the performance and quality of over 500,000 installed seats of CAD/CAM and CNC software around the world. From standard products to exclusive development projects, ModuleWorks helps companies to bring their vision of Industry 4.0 to life. With its comprehensive portfolio of cutting-edge software components, ModuleWorks enables its customers to optimize their CAD/CAM solutions and connect to CNC/MTB systems to increase their competitiveness and help them Get There Faster.