ModuleWorks’ Innovative Additive Manufacturing Won a Research Award!

Since 1983, the International Manufacturing Conference in China (IMCC) takes place every other year and features all fields of advanced manufacturing. For the 2021 International Manufacturing Conference over 300 papers have been sent to the conference to present excellent up-to-date research. The paper sent in by ModuleWorks stood out – Quality Implications of Applying 3+2 Axis Toolpaths in 3D Printing won the Third Prize Paper Award!

The algorithm for 3+2 printing described in the paper overcomes limitations of additive technologies. Traditionally, it is not possible to print surfaces at 45 degrees or more which are called overhangs. While the 45-degree-limit can be circumvented with the help of support structures, the process and the result are far from optimal. Support structures must be removed afterwards – and therefore are a waste of time, material, and energy. Even worse is that the surface areas that were connected to support structures have irregularities such as residual material or scars.

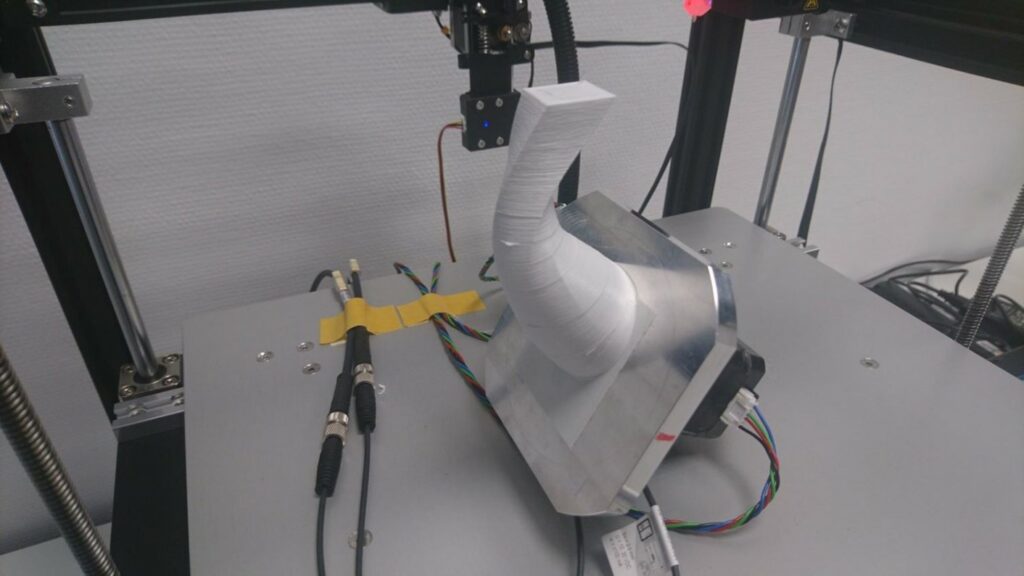

Multi-axis deposition strategies such as the 3+2 strategy can master this limit without support structures with a rotary-tilt-table, resulting in faster processes and better surface quality while not requiring additional time or energy. In the 3+2 strategy, material is deposited in flat layers, but not all layers are parallel to each other. Instead, layers are deposited in chunks that change the direction. A special feature of ModuleWorks software is the collision avoidance for part branches and the rotary-tilt table which is incorporated to check for possible collisions of the movable parts and to prevent them during manufacturing.

At ModuleWorks, research activities and practical additive production fuel each other’s success: while the algorithm has been developed to improve additive processes and to increase customer satisfaction, it furthermore provided the basis for thorough investigation. Uniting both, improved printing led to an excellent paper.

The PDF of the paper is linked below for details.