Get Your Free Demo

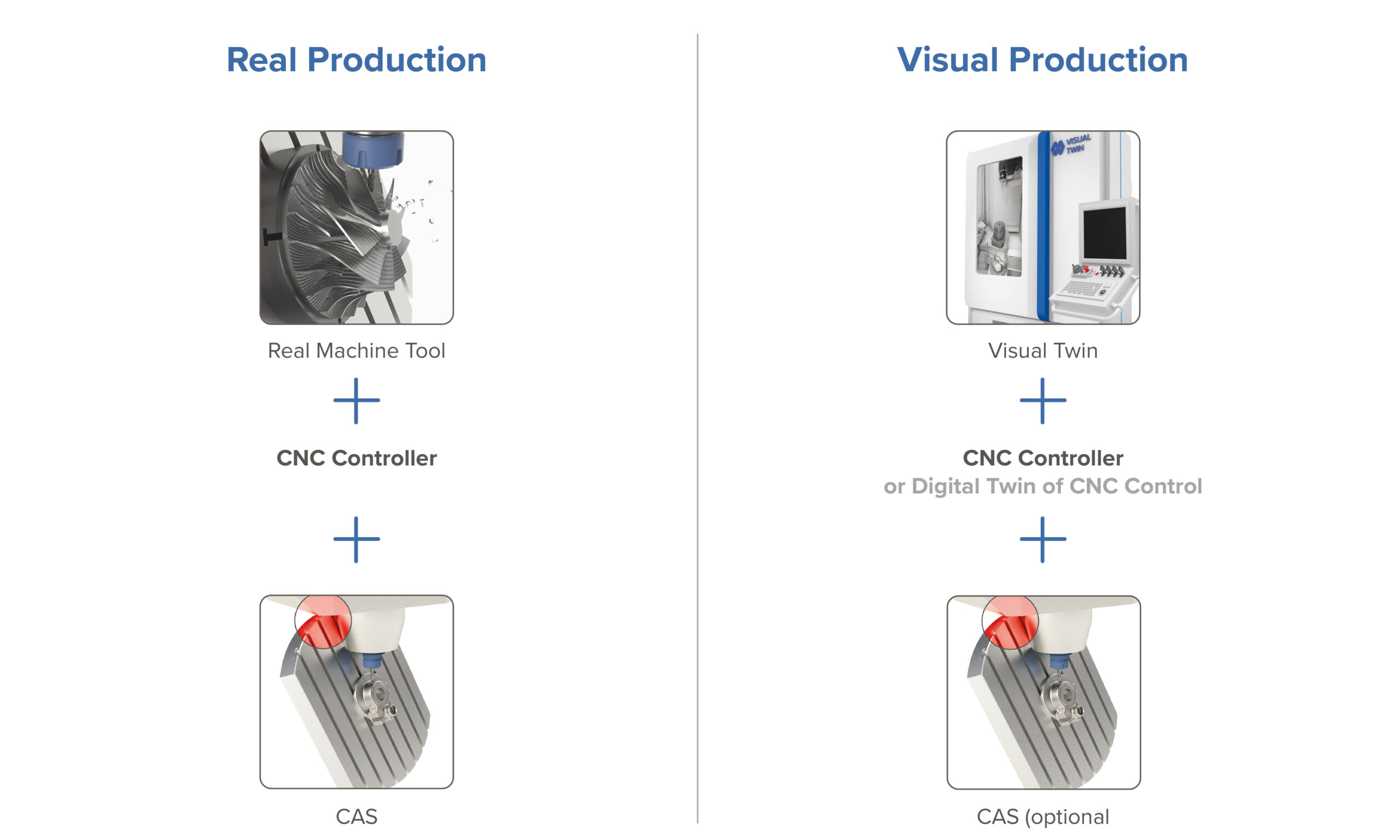

See for yourself how the VISUAL TWIN offers you up to 75% cost savings and helps you bring the next generation of industry 4.0 to life.

VISUAL TWIN Features

Realistic graphics and authentic effects

- Shadows, lighting and textures

- Flying chips and machining sounds

High performance

- Standalone software application running on a separate PC

- Works on consumer-grade hardware

- Runs in real-time

Compact

- Screen and PC/CNC (optional) are sufficient

Use Cases

Sales

Live on-site demonstrations showing the customer's own parts

Prepare persuasive pre-recorded online demonstrations of customer-specific scenarios

Easy to set up customer parts and scenarios compared to a real machine

Low cost and low risk

Impressive animated authenticity

Marketing

Eye-catcher that attracts new leads to the booth

Show multiple machines and machine series at a single exhibition

Easily create your own online marketing content

Cost-efficient deployment at exhibitions

Low footprint because no machine hardware is needed

Innovative, new and highly realistic

Training

Train operators/students on your machine and CNC control

No risk of machine damage

Gaming-like authentic technology through acoustic and visual effects

Your Benefits

VISUAL TWIN Services

Photo-realistic modelling of the machine and process

Integrate your control and PLC

Connect to your CAM system to model machining processes

Consultation to customize the

VISUAL TWIN to deliver your key sales/marketing/training messages