Frankfurt is the hub for all things Additive, and we’d love to connect with you at the show. Visit the ModuleWorks booth to try our new Automation Framework (MADF) and see how you can quickly build integrated workflows for more efficient hybrid manufacturing — from print to post-processing.

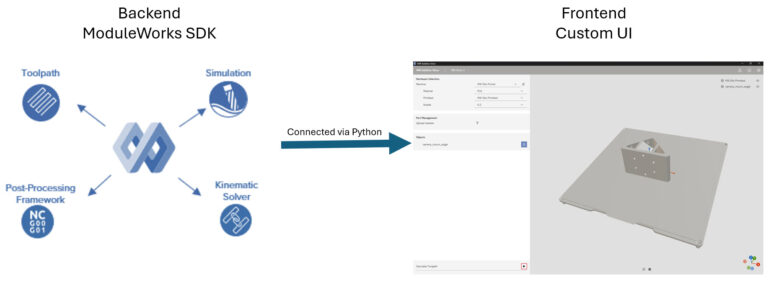

MADF - Manufacturing Application Development Framework

When developing a new robotic cell or additive application, such as WAAM or DED, it’s essential to have reliable backend software for toolpath generation, simulation and post-processing, along with an efficient, intuitive user interface.

MADF is a modular Python framework that simplifies and speeds up this software development process. It provides direct access to the ModuleWorks SDK, enabling you to quickly build powerful, user-friendly workflows without diving into low-level programming. With MADF you focus on creating intuitive interface functionality while the framework takes care of integration with the ModuleWorks toolpath, simulation and post-processing technology.

MADF is designed for scalability. You can start small with a single process or interface and expand as needed by adding modules for new machines, materials or applications. The result is a flexible, maintainable software foundation that supports rapid development and a consistent user experience across your manufacturing solutions.

From Print to Perfection: An Integrated Hybrid Workflow

Picture a rocket nozzle, turbine blade or injection mold being printed with WAAM, DED, or robotic additive processes and then handed over for subtractive machining before applying final surface treatment.

ModuleWorks offers a single, consistent environment for the entire workflow, from additive parameter control and intelligent subtractive programming to efficient post-processing, helping you produce parts faster, with higher accuracy and fewer manual iterations.

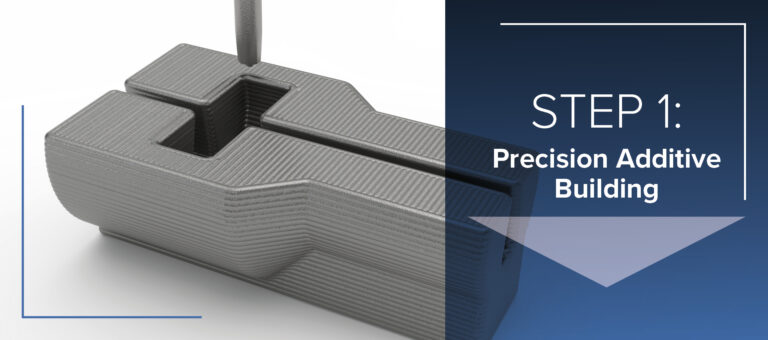

Step 1: Precision Additive Building

The additive process begins with transforming raw material into a near-net shape. Layer by layer, metal is deposited until the shape emerges. ModuleWorks Additive components give you built-in control and adaptability over the entire process for efficient and flexible high-quality deposition with:

- Automated Parameter Optimization

- Flexible Toolpath Patterns

- Split Mesh & Custom Start Points

These features and more enable engineers to strike the right balance between speed, precision and efficiency across a wide range of additive and robotic processes.

Step 2: Smart Subtractive Finishing with NGSP

Once printed, the part needs to be brought to its final contour. This is where ModuleWorks Next Generation Shopfloor Programming (NGSP) steps in. The imported CAD geometry defines the exact target shape. NGSP automatically recognizes machining features and guides the operator in generating the required toolpaths. With intelligent tool and parameter selection, NGSP ensures the subtractive finishing is fast, precise and aligned to design intent — no deep G-code knowledge is required:

- Touch-Based Feature Detection

- Automatic Tool & Parameter Recommendation

- Support for Multiple Features & Machining Modes

- Stock-Aware Smart Machining & Verification

In benchmark tests, NGSP delivered 70% faster on-machine programming compared to G-code and was up to 50% faster than traditional conversational systems while also reducing programming errors and cycle times.

Visit our NGSP webpage to learn more.Step 3: Robust Postprocessing

To ensure the parts meet performance demands, ModuleWorks supports advanced surface treatment workflows:

- Hammer Peening – Automatically generate peening toolpaths with consistent step-over, impact force control, side tilt and lead/lag angles and intelligent linking to ensure a smooth, repeatable surface finish.

- Laser Hardening – Ensure precise surface treatment by automatically defining curved hardening paths, beam width and penetration settings for high-quality hardening with minimal manual input.

The Result: Smarter, Faster Manufacturing

Integrating additive, subtractive and post-processing in a unified workflow translates into tangible shop floor benefits for smarter, more efficient production:

- Streamlined handoffs and faster development cycles

- Reliable, high-fidelity results with less operator effort

- Greater freedom to handle complex geometries without extensive manual prep

Formnext Awards

ModuleWorks is proud to be part of the Formnext 2025 Ambassador and Sustainability Awards.

The Sustainability Award recognizes technology that reduces waste and energy consumption across the entire process chain. For the Ambassador Award, we’ve entered our innovative 3+2 software, which helps reduce lead times, costs and tooling for additive and hybrid processes.

Find out more in our videos below!

AMbassador Award

Sustainability Award

Talk to an Expert – Book a Meeting at the Show

Ready to discover how ModuleWorks can transform your additive and hybrid manufacturing? Speak with our experts at Formnext 2025 and explore ways to bring your manufacturing ideas to life.

To schedule a meeting, simply click the button below!

Where to find us: Hall 11, Booth 29

We’re looking forward to seeing you soon in Frankfurt!

Your ModuleWorks Team