Material removal simulation involves processing vast numbers of geometric interactions with every tool move, potentially reshaping the stock model. These calculations are perfectly suited for the thousands of parallel cores found in GPUs. ModuleWorks taps into that power to run calculations in parallel, dramatically reducing simulation times and freeing up engineers to focus on programming, validation and production.

GPU Simulation performs material removal and collision detection directly on the graphics processor, leveraging thousands of parallel cores to simulate toolpaths with high efficiency. This approach allows even very large and complex programs to be simulated with far greater efficiency than traditional CPU-only methods.

Designed for seamless integration into existing CAM solutions, ModuleWorks GPU Simulation makes high-performance verification accessible to users directly within their familiar CAM environment.

Major Challenges

Inefficient Programming Feedback

Traditional CPU-based simulation often requires minutes or even hours to process large toolpaths, limiting the number of iterations that programmers can realistically verify. This delay forces programmers to limit variation cycles or push deadlines.

Complex Toolpaths and Large Models

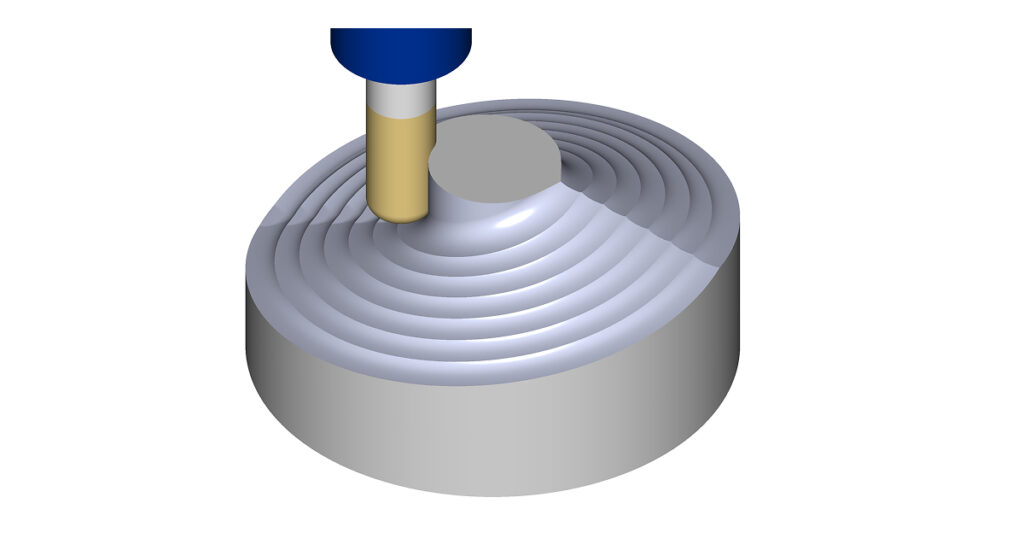

High-speed machining, 5-axis strategies, and additive processes generate massive toolpaths with millions of moves. On the CPU, these calculations are processed with limited parallelism, causing the workload to scale poorly as complexity increases.

Bottlenecks in

Verification

Without fast and accurate simulation, programmers may compromise accuracy for performance or skip verification steps. This introduces risk, as undetected collisions, gouges, or excess material lead to higher costs.

Limited Accessibility of High-Performance Simulation

Historically, achieving high-performance simulation often required costly specialized hardware setups. This reinforced a gap between programming needs and available computing power.

Solution Offered by ModuleWorks

Key Features

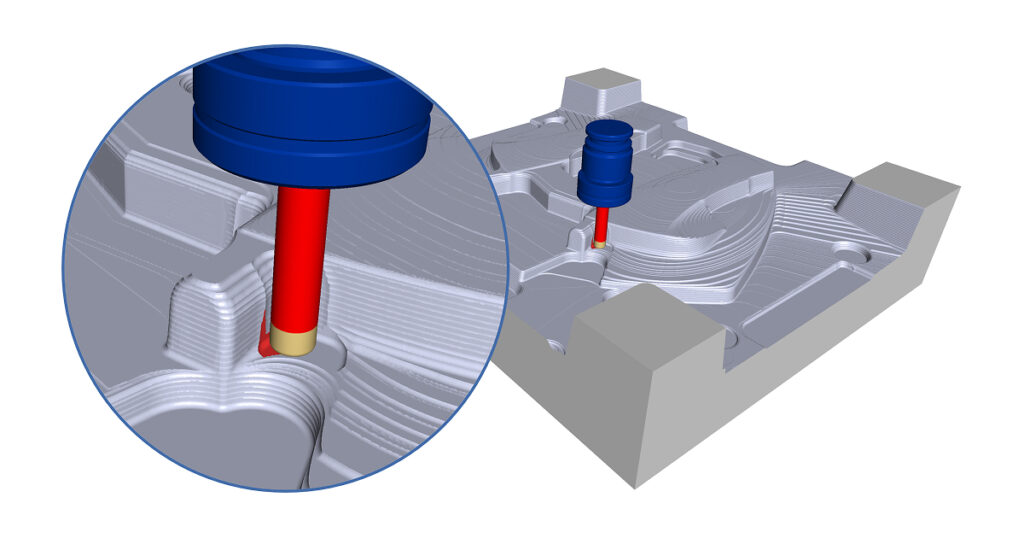

Material removal simulation is at the core of verifying machining processes, and its reliability depends on accurate tool–stock interaction. Precise collision checking and stock updates are critical for avoiding machine crashes and wasted material. GPU acceleration performs material removal updates and collision detection simultaneously across multiple cores, reducing computation time dramatically. The result is faster simulation cycles without sacrificing the accuracy required to detect gouges, collisions, or other critical errors.

The system automatically detects and selects the best available GPU, with performance scaling directly with hardware capability. A better GPU will usually result in significantly better performance. Compatible with discrete GPUs from major vendors such as NVIDIA and AMD, it brings high-performance simulation to a wide range of workstations without specialized hardware, with full support for both Windows and Linux environments.

Key Benefits

Accelerated toolpath verification with significantly reduced simulation time

High-fidelity simulation with pixel-accurate inspection for reliable analyses

Faster, more precise stock updates for efficient tracking of in-process material