FeedControl

Take Your CNC Machining to the Next Level with FeedControl’s Intelligent Feed Rate Optimization.

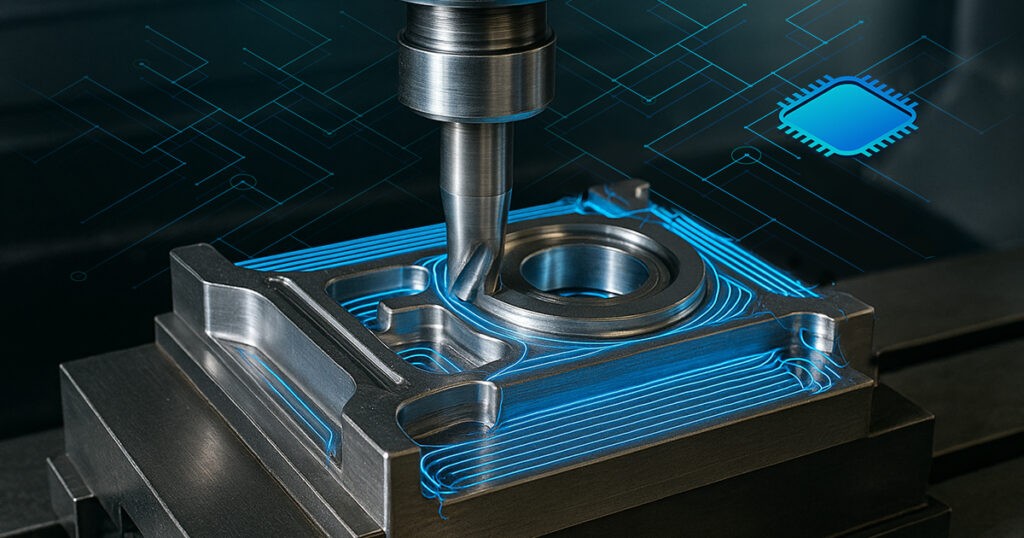

FeedControl is the fastest way to unlock superior machining, delivering optimal performance, consistent quality, and longer tool life across demanding production environments. By intelligently optimizing toolpaths, FeedControl automates feed rate and toolpath values to maintain stable cutting forces and chip thickness, minimizing air cuts and non-cutting moves while respecting machine and tooling limits.

Major Challenges

Unpredictable Machining Performance

Traditional CAM systems ignore real-time cutting forces and spindle load, leading to quality risks, tool failures, and costly downtime.

High Programming Overhead

Expert intervention is required to fine-tune toolpaths, wasting skilled time and slowing production planning.

Lost Productivity

Conservative parameters extend cycle times, underutilize machine capacity, and drive up unit costs in competitive markets.

Inconsistent Results

Less experienced programmers struggle to generate optimized toolpaths, leading to inconsistent output and performance.

Solution Offered by ModuleWorks

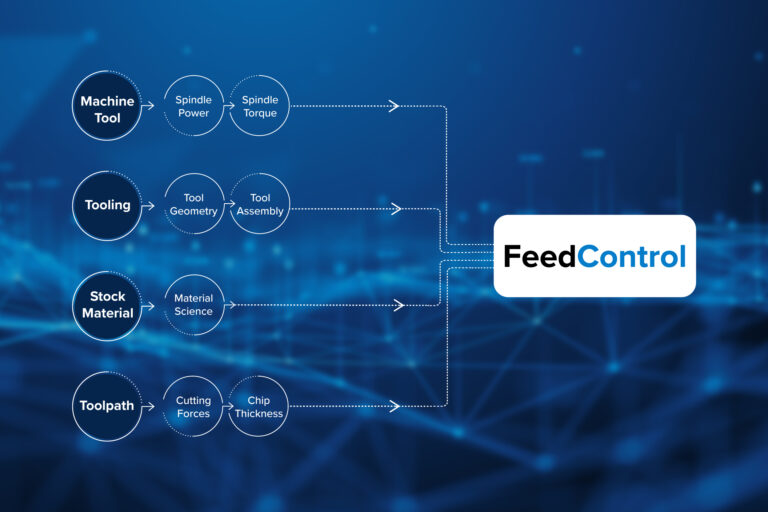

ModuleWorks FeedControl enhances existing toolpaths by using a physics-based engine. It considers the spindle torque and power, tool properties, raw material, and spindle interface to deliver a constant chip load and consistent cutting conditions throughout the machining process, resulting in overall higher productivity.

Key Features

FeedControl uses a proprietary physics-based chip modeling engine to optimize toolpaths, ensuring precise chip formation and safe operations. By evaluating cutting forces, spindle load, and material removal rates, machinists achieve expert-level results without requiring advanced programming expertise.

FeedControl’s dynamic load monitoring continuously adjusts feed rates to maintain optimal spindle utilization throughout the machining cycle. Instead of using static feed rates, it ensures consistent cutting forces and prevents overload conditions that can damage tools and compromise surface quality.

FeedControl automatically identifies opportunities for feed rate optimization and toolpath efficiency improvements. The software’s intelligent algorithms maximize material removal rates while staying within safe operating parameters, delivering measurable cycle time reductions without operator intervention.

Key Benefits

Reduces cycle times and generates precision-optimized toolpaths

Maintains consistent spindle load for predictable cutting dynamics

Extends tool life through optimized cutting forces and controlled engagement