High Dynamic Turning

Break Free from Fixed Angles: High Dynamic Turning Redefines Manufacturing Possibilities

Traditional turning cycles struggle with fixed cutting angles, requiring multiple tool changes and setups for each machining feature – from roughing to finishing to undercuts. Each angle adjustment demands repositioning or new tooling, while part family changes require complete retooling and reprogramming. Multi-tasking machines with High Dynamic Turning eliminate these bottlenecks by dynamically adjusting cutting angles in real-time, transforming turning from a tool-heavy, sequential process into a flexible, efficient operation. This removes the constraints of fixed tools and limited approach angles, unlocking the full potential of modern turn-mill centers.

Major Challenges

Frequent Tool Changes Between Machining Operations

Traditional turning requires constant tool changes between machining operations, multiple setups for each part feature and complete retooling for different part families. This disrupts production and causes downtime from angle adjustments and repositioning.

Multiple Setups and Excessive Downtime

Fixed-angle turning tools struggle with complex contours, undercuts, and varied part geometries. Manufacturers often require specialized tooling or multiple setups to handle diverse geometric requirements, increasing complexity and programming time. This affects productivity due to sequential processing limitations.

Underutilization of Spindle Orientation on Multitasking Machines

Integrating spindle orientation on turn-mill machines often introduces complex programming challenges, which can reduce overall machine utilization. Without HDT technology, it becomes difficult to fully leverage the capabilities of these turn-mill centers.

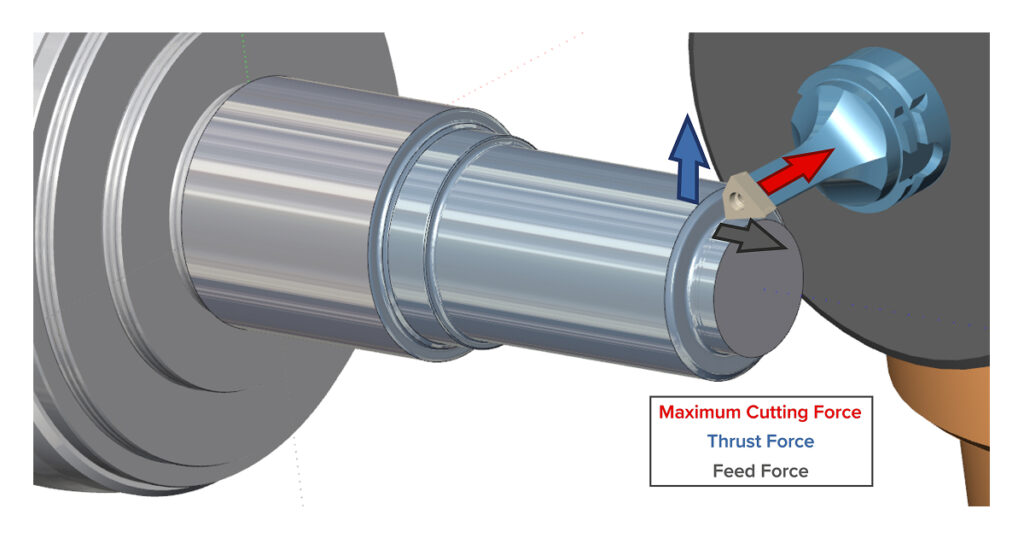

Suboptimal Chip Control and Process Stability

Traditional turning methods result in poor chip formation and evacuation, leading to tool wear, poor surface quality, and process instability. Operators are often forced to compromise on cutting parameters to avoid chip-related problems.

High Tooling Costs and Inventory Management

Using multiple specialized tools for different operations increases tooling costs, complicates inventory, and adds operational complexity for machine shops.

Solution Offered by ModuleWorks

High Dynamic Turning unleashes the full potential of multi-tasking machines by dynamically adjusting cutting angles in real-time. This breakthrough technology transforms your manufacturing operation from tool-heavy, sequential processes into flexible, efficient production.

Key Features

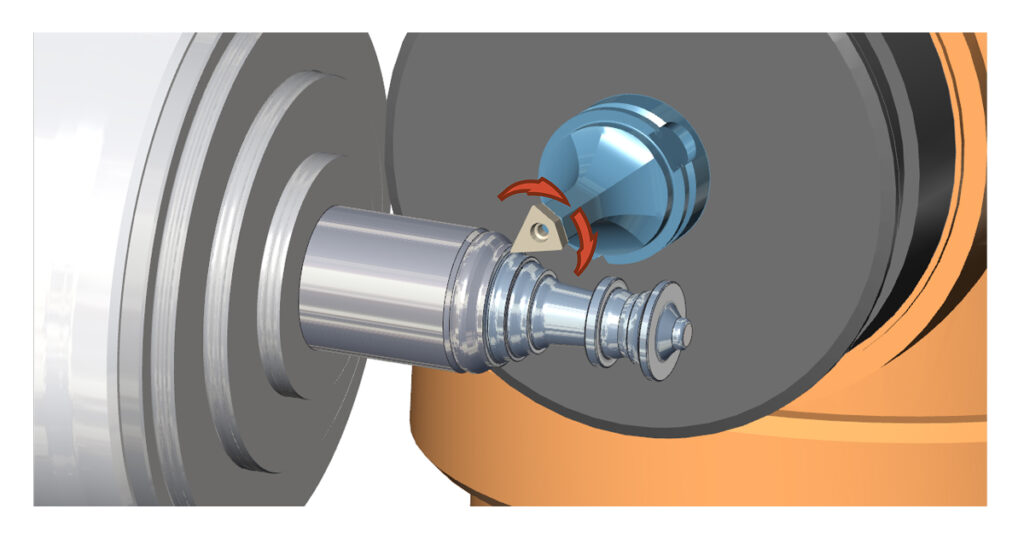

High Dynamic Turning uses the milling spindle (C-axis) of turn-mill centers to continuously adjust the tool’s approach angle in real time without manual intervention. This dynamic positioning enables optimal control of the cutting edge and side cutting angle at any point in the process without interrupting the machining operation.

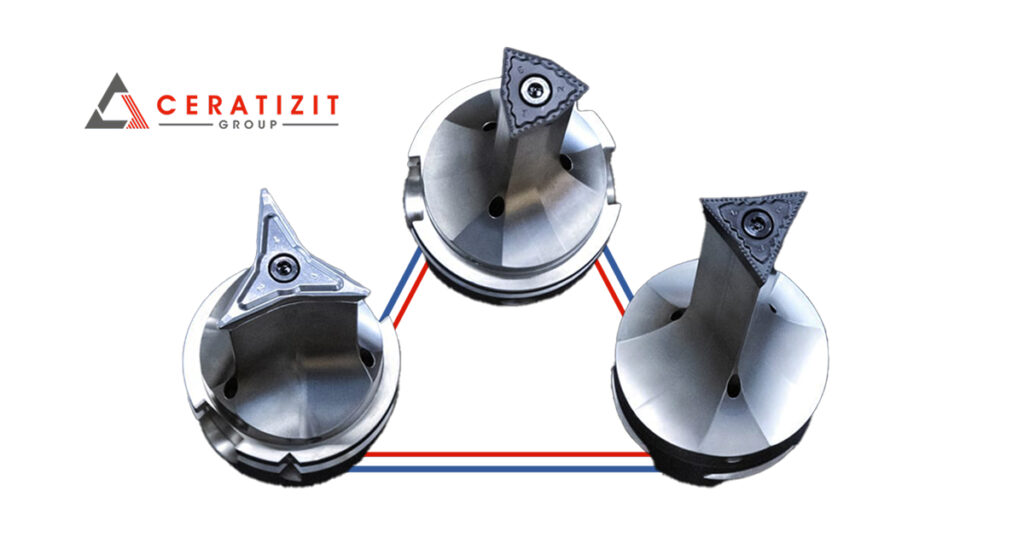

All the standard turning operations – roughing, finishing, grooving, contour turning, face turning, and longitudinal turning – can be performed with one FreeTurn tool from Ceratizit. This eliminates the need for multiple tool changes and reduces setup complexity, leading to seamless transitions between roughing, finishing, and undercut operations.

Key Benefits

Up to 25% cycle time reduction with maximized output through continuous operation

Reduced changeover times between part families with optimized resource utilization across production runs

Superior surface finish with flexible approach angles and optimized chip control

Machine complete complex parts in a single setup