SmartRoughing

Transform Your Roughing Operations Through SmartRoughing with Integrated Kennametal Tooling

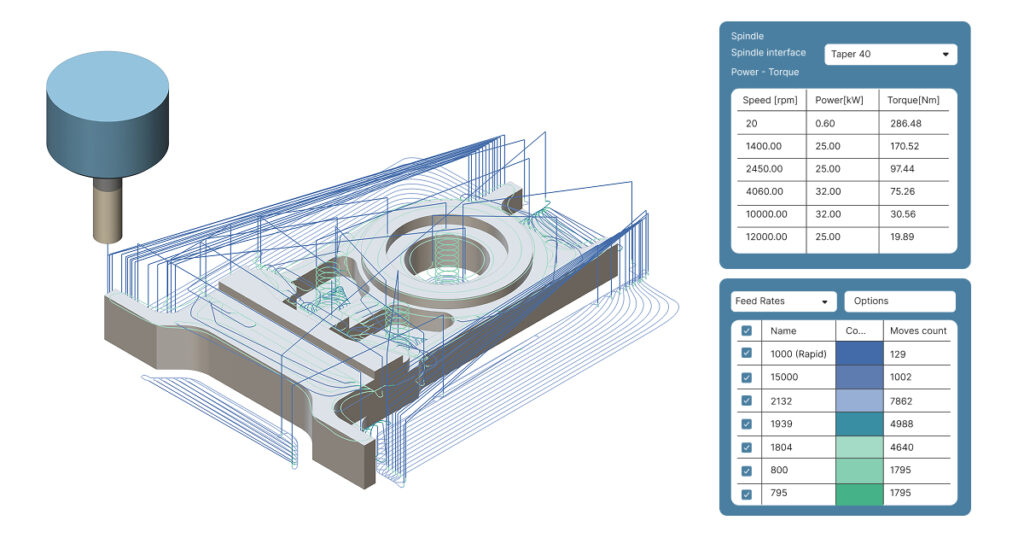

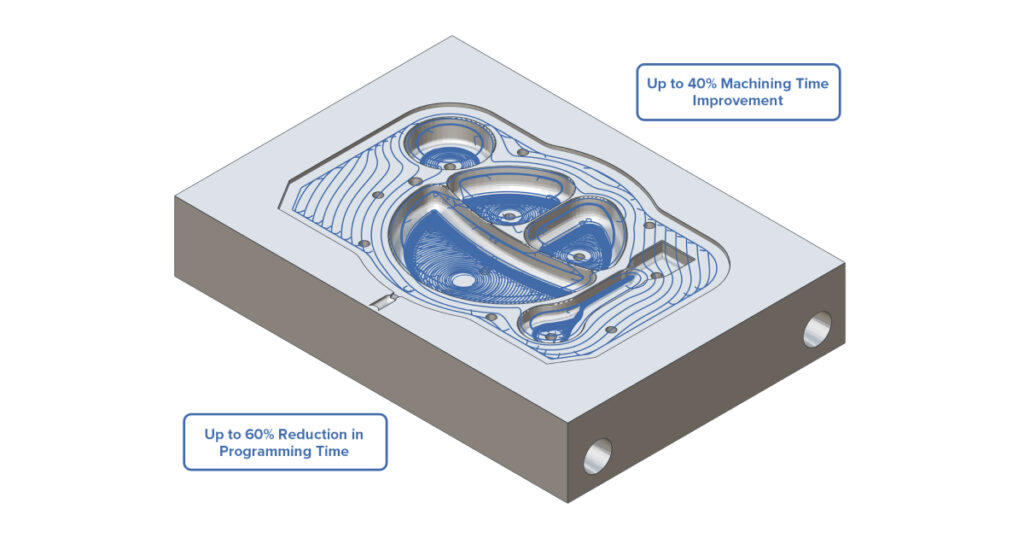

SmartRoughing by ModuleWorks is a next-generation intelligent roughing strategy for 3-axis machining that applies a physics-based engine to optimize cutting forces, chip load, and material removal rates for high-performance machining. This advanced system analyzes the part topology and automatically fine-tunes critical variables including stepover, stepdown, feed rates, and spindle speed to deliver faster, safer, and more efficient roughing operations – especially effective in high-throughput production environments.

Major Challenges

Manual Parameter Selection and Programming Complexity

Conventional CAM systems require programmers to manually determine optimal feeds, speeds, stepover distances, and cutting depths based on experience and trial-and-error approaches. This process is time-consuming, inconsistent, and often results in suboptimal parameters that compromise either productivity or tool life, creating bottlenecks in production workflows.

Inconsistent Cutting Conditions and Tool Engagement

Traditional roughing strategies frequently create uneven tool loading conditions, leading to unpredictable cutting forces, vibrations, and thermal stress. These inconsistencies cause premature tool wear, surface quality issues, and potential tool breakage that disrupts manufacturing schedules and increases operational costs.

Skills Gap and Operator Expertise

The growing shortage of experienced CNC programmers is making it increasingly difficult to select optimal roughing parameters. As a result, many shops struggle with inconsistent results when less experienced operators are forced to make complex machining decisions without a deep understanding of cutting dynamics and material behaviour.

Solution Offered by ModuleWorks

ModuleWorks SmartRoughing is an automated, physics-based strategy for 3-axis CNC machining that calculates optimal toolpaths for stable, efficient material removal. By analyzing machine and tool dynamics, it maximizes productivity with minimal user input and integrates seamlessly into CAM systems for safe, high-performance roughing.

Key Features

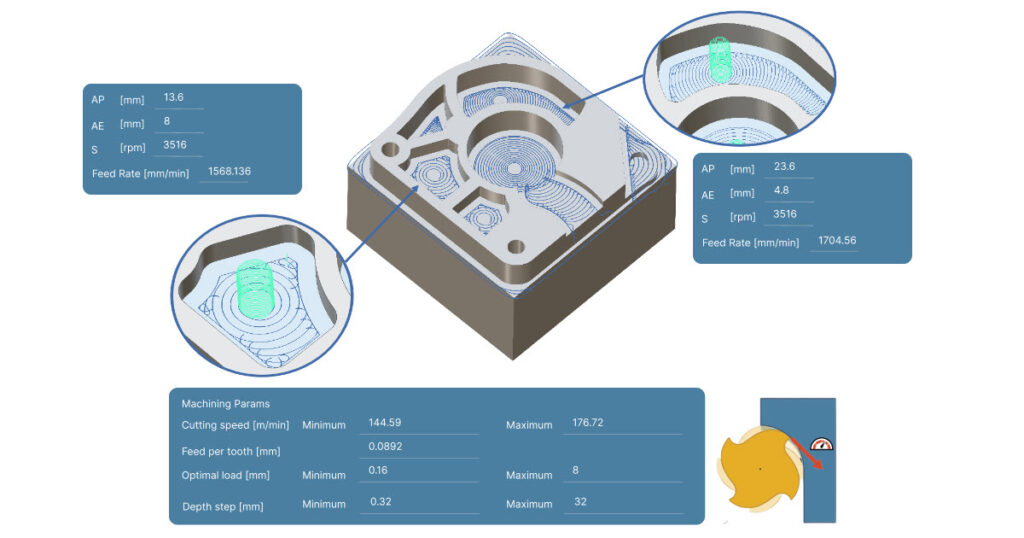

Unlike geometry-based optimizers, SmartRoughing employs physics-based simulation to analyze the actual machining process. It calculates critical forces, including chip load, side load, and torque. By balancing these dynamics with the CNC machine’s power and feed limits, it generates a highly optimized and physically accurate toolpath.

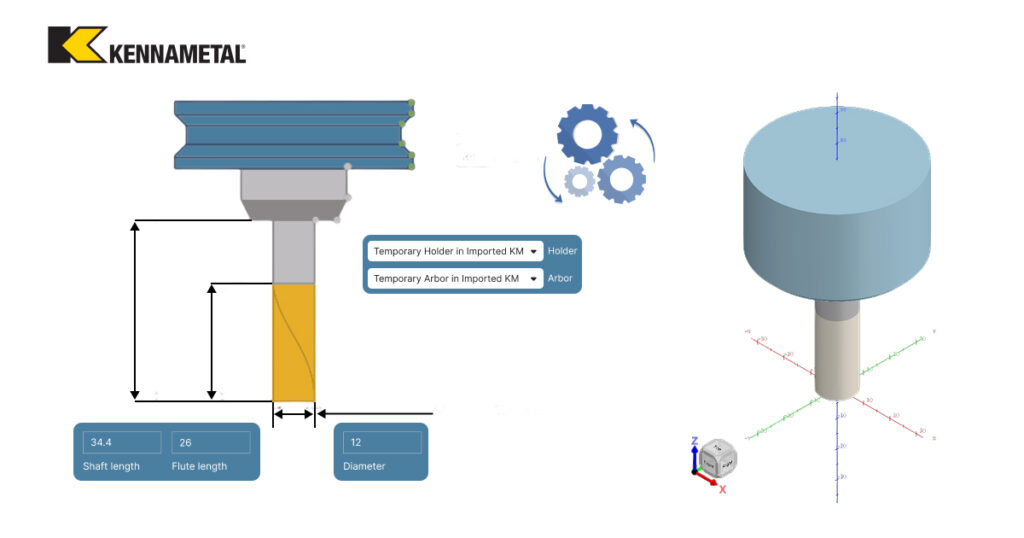

SmartRoughing utilizes Kennametal’s materials science expertise and robust application knowledge to optimize cutting operations. Kennametal’s comprehensive tool database contains tool geometries, cutting coefficients, and material-specific parameters which are integrated in SmartRoughing and fed into the physics engine.

SmartRoughing’s patented algorithm analyzes part geometry and automatically selects the best toolpath parameters to maximize material removal rates. By leveraging cutting physics principles, it chooses appropriate process parameters for each geometric feature, ensuring efficient roughing operations while maintaining machine protection and high-quality cutting across diverse part geometries.

SmartRoughing delivers unparalleled performance by combining physics-driven machining intelligence with patented, area-based toolpath optimization. This next-generation strategy analyzes part topography to create dynamically adaptive toolpaths, ensuring faster, safer, and more efficient 3-axis machining. It replaces traditional methods for a truly intelligent and automated roughing process.

Key Benefits

Dramatically reduced cycle times and enhanced programming efficiency

Extended tool life thanks to physics-based optimization

Seamless integration and scalability

Improved surface quality through consistent tool engagement and controlled cutting forces