Software Release 2025.08 Highlights

ModuleWorks has unveiled its 2025.08 software release, setting a new standard for intelligent manufacturing solutions. This update introduces advanced features that redefine toolpath generation and simulation, including revolutionary 5-axis roughing, adaptive toolpath algorithms, and lightning-fast simulation performance. Enhanced collision detection and real-time feedback empower users to optimize processes and prevent costly errors, while improved support for complex geometries and a more intuitive user interface make it easier than ever to tackle challenging projects. With expanded API capabilities and seamless integration across components, ModuleWorks 2025.08 delivers the flexibility, precision, and productivity manufacturers need to lead in the era of smart manufacturing.

Toolpath

Multi-Axis Surface Finishing | Geodesic Machining

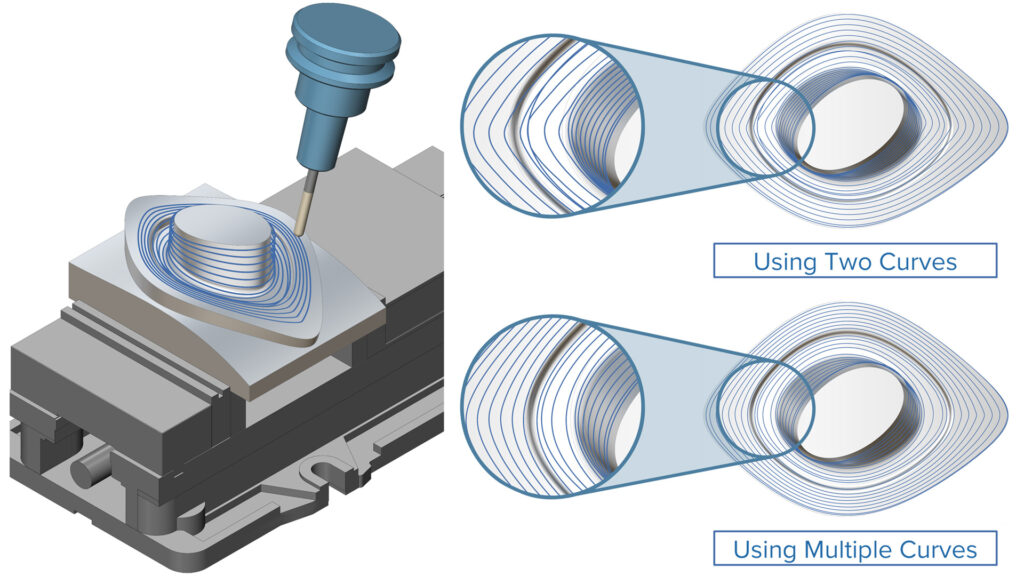

Morph Between Multiple Curves

Challenge: For parts with strong curvatures, edges, or twisted surfaces, users previously had to create multiple morph operations to achieve a consistent pattern, increasing programming time and complexity.

Solution: This enhancement consolidates multiple morph operations into one, enabling seamless transitions across different areas of the part while maintaining pattern quality.

Benefits: The result is faster programming, smoother toolpath patterns, and support for efficient cutting methods like spiral machining.

Multi-Axis Surface Finishing | Geodesic Machining

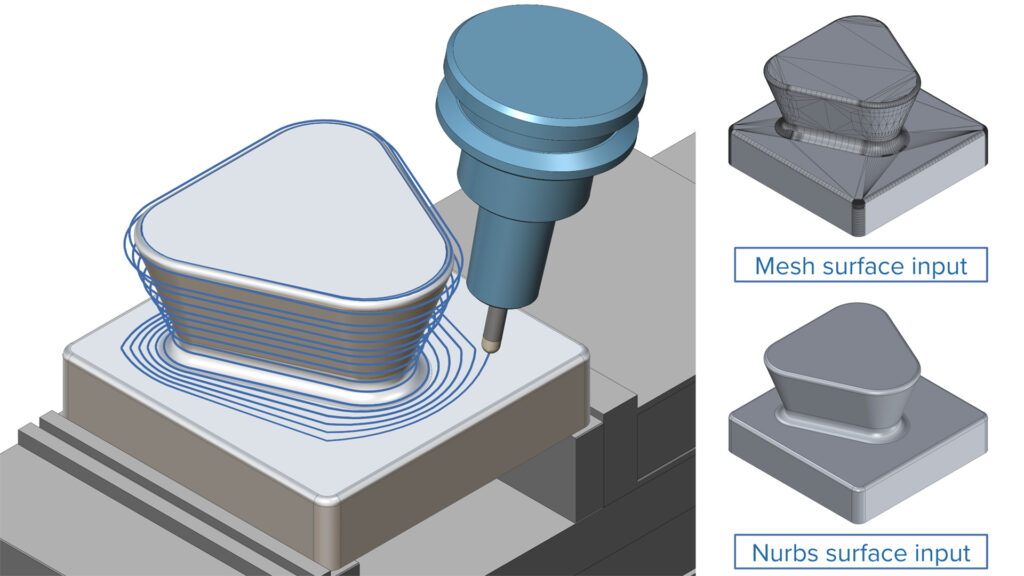

NURBS Surface Support

Challenge: Previously, converting NURBS surfaces to triangle meshes introduced errors, discontinuities and artifacts, which reduced toolpath accuracy and surface quality.

Solution: By using NURBS surfaces directly in the Geodesic core, the toolpath calculation now has access to the precise geometry, eliminating the inaccuracies caused by mesh conversion.

Benefits: This feature is designed to benefit users who have high quality NURBS surface.

Multi-Axis Surface Finishing | Geodesic Machining

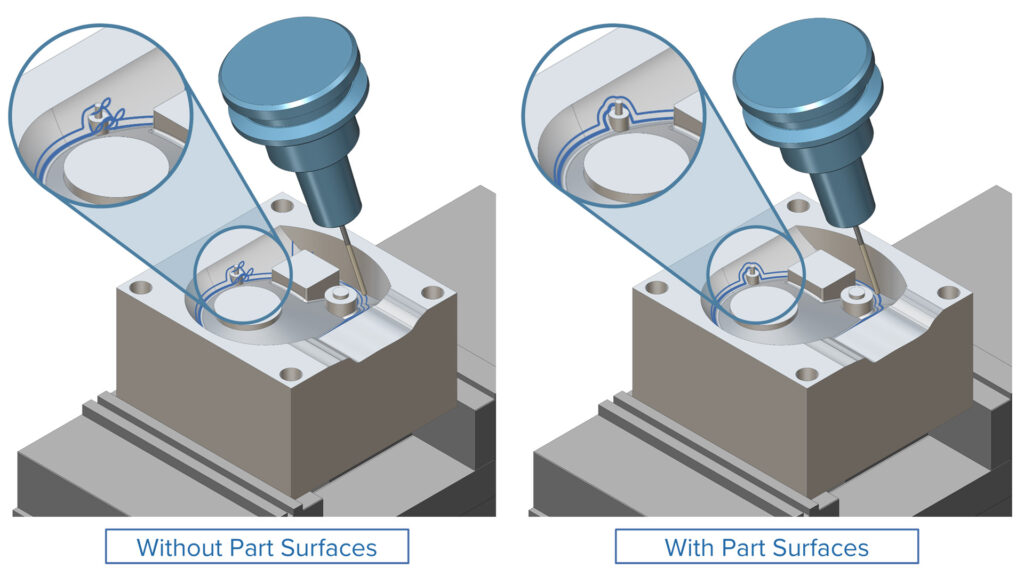

Part Awareness for Pattern Generation

Challenge: Previously, Geodesic toolpaths ensured collision-free toolpaths only for the spherical tool tip in relation to the machining surface. Adjacent geometries, such as walls, had to be manually defined as check surfaces, often resulting in trimmed or suboptimal toolpaths.

Solution: The updated Geodesic Tool-Center mode now supports full part geometry input, enabling the generation of collision-free toolpaths for the spherical tool tip. To ensure complete safety, users should enable collision control to guarantee a collision-free path for the entire tool body. Additionally, users can define extra clearance values relative to the part surfaces for enhanced control and safety.

Benefits: This feature delivers more natural, collision-free toolpaths, minimizes manual setup and enhances overall machining safety.

Multi-Axis Edge Finishing | Deburring

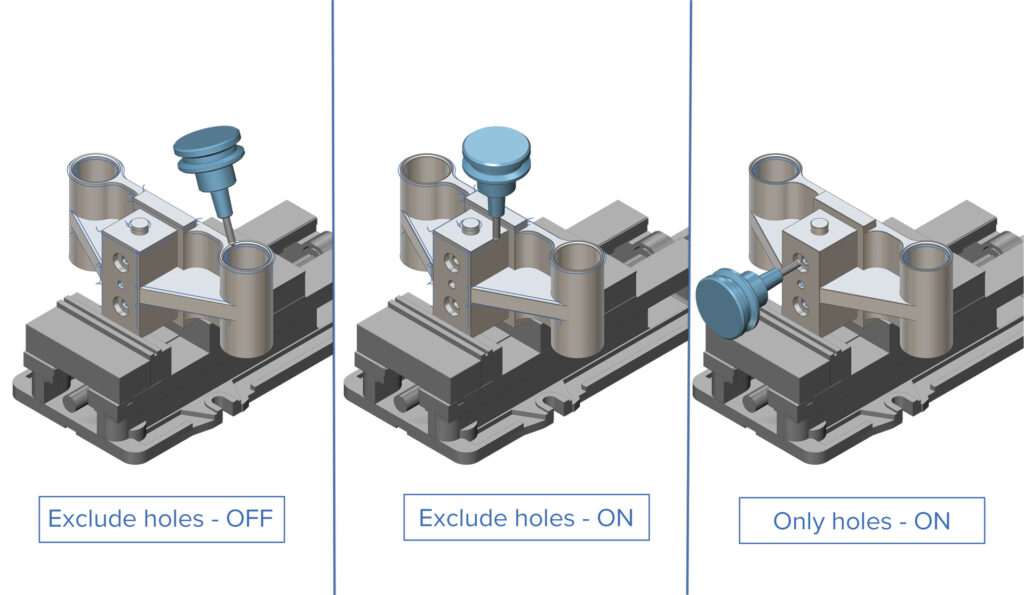

Exclude Holes and Vertical Edges

Challenge: Currently, holes are sometimes deburred twice with a spot drill, and there’s no way to exclude holes below a certain diameter. Additionally, the system cannot prevent unwanted deburring of vertical edges in a 3-axis setup.

Solution: Now, there is an option to filter out holes and vertical edges while deburring.

Benefits: This feature enhances ease of use and flexibility when working with the geometry, enabling edge selection that fully aligns with cutting process requirements.

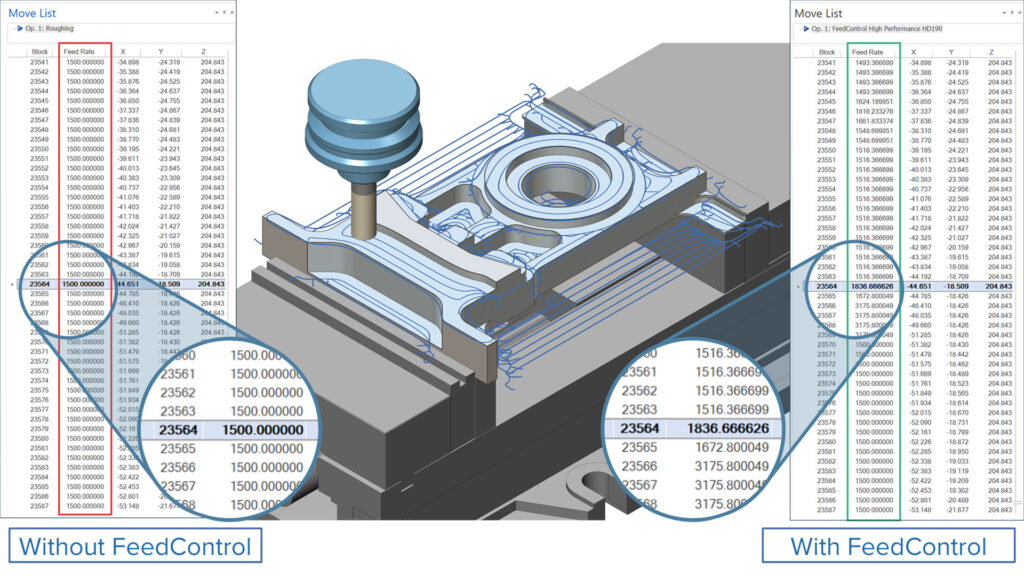

Core Component Technologies | FeedControl

Introducing FeedControl

Challenge: Achieving consistent chip formation across the entire toolpath has been difficult due to varying factors such as heat dissipation, tool load, spindle deflection and workpiece hardening. Controlling all these elements across different machining operations is time consuming and difficult.

Solution: FeedControl intelligently balances peak chip thickness, cutting forces and machine spindle loads to ensure precision and tool longevity. By leveraging material properties, machine-tool capabilities and cutting-tool geometry, it fine-tunes feedrates for an optimal machining process.

Benefits: FeedControl enhances productivity, minimizes programming errors and ensures safe, high-performance machining operations, especially in shops facing skills gaps. It delivers a high-quality surface finish, reduced cycle times and extended tool life.

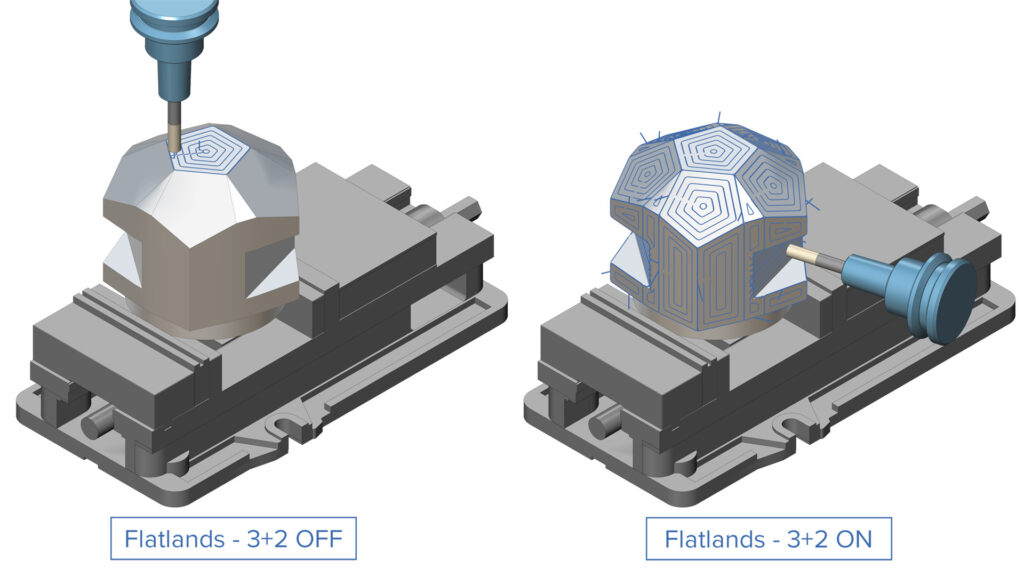

3-Axis Finishing | Mesh Finishing

Automatic 3+2 Flatland Finishing

Challenge: Users often face challenges identifying the correct machining direction for flatlands, leading to mistakes and inefficiencies. As the number of flatlands increases, so does the likelihood of errors, slowing down production and compromising quality.

Solution: Now, a new option automatically detects flatlands and determines the optimal machining direction—all in a single operation.

Benefits: With this new feature, users can easily generate toolpaths for machining flatlands in significantly less time. The automated process streamlines the workflow and ensures consistent part quality.

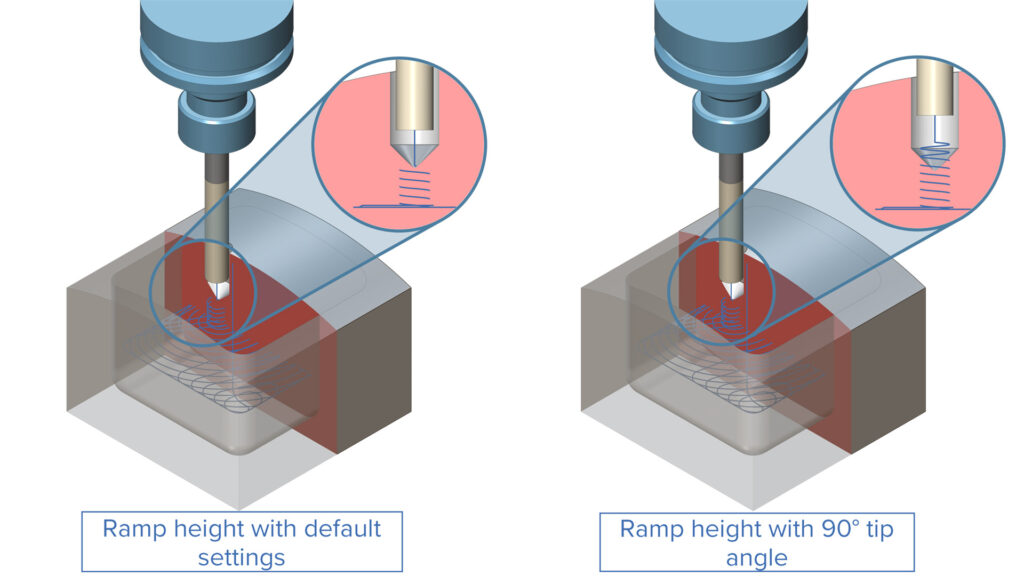

3-Axis Roughing | Adaptive Roughing

Ramp Height Control Inside Pre-Drill Hole

Challenge: When programming toolpaths for machining operations that start inside pre-drilled holes, the ramp height is often set relative to the top of the surrounding stock area. This approach leads to the tool performing unnecessary air cuts above the actual workpiece. As a result, the tool slows down (decelerates) too early, even though a rapid approach through the pre-drilled hole would be possible. This inefficiency increases the overall machining time and production costs.

Solution: Introducing the new ‘Drill Tip Angle’ parameter. The algorithm uses this parameter to automatically adjust the ramp height based on the height of the drill hole’s conical section, referencing the specified drill point position.

Benefits: With this new feature, adjustments in the ramp height are controlled by the height of the drill hole conical section. This reduces unnecessary air cuts and optimizes total machining time.

3-Axis Roughing | SmartRoughing

SmartRoughing

Challenge: The toolpath programmer needs to consider all the physical variables within the process to ensure optimal MRR without risking tool wear, machine overload, or loss of stability. Traditionally, this depends heavily on the programmer’s experience, leaving novice users uncertain and often hesitant about their parameter choices.

Solution: The SmartRoughing toolpath algorithm analyzes part geometry and leverages cutting physics to select optimal process parameters. It integrates machine power and torque limits, spindle interface rigidity, tool and holder length, tool geometry and flute count, and workpiece material properties. These factors are dynamically combined to generate toolpaths with constant tool engagement and optimized chip load for efficient roughing.

Benefits: SmartRoughing offers significant advantages to manufacturers and users:

- Increased productivity due to reduced cycle times and optimized machine use.

- Improved tool life due to better cutting conditions.

- Reduced manual process adjustments thanks to automation.

- Better surface quality and precise machining, even on complex geometries.

- Less dependency on skilled professionals.

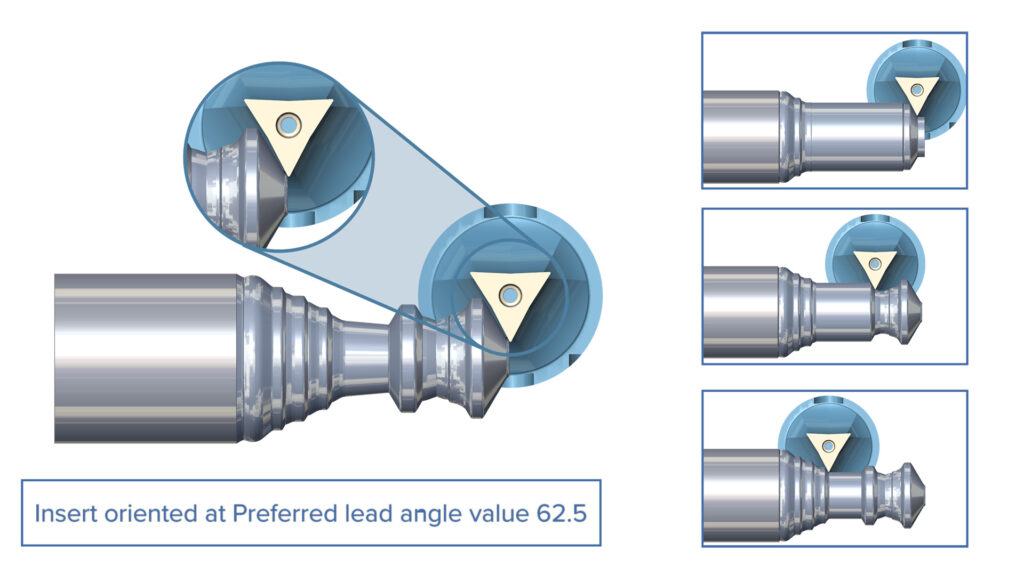

Turning | High Dynamic Turning

Static Roughing in High Dynamic Turning

Challenge: In conventional turning, it was not possible to create the toolpath in the Y-Z plane, and users could not specify the lead angle for the tool insert.

Solution: With this new feature, users can specify the lead angle using the FreeTurn tool.

Benefits: With this new feature, users can easily generate toolpaths in the Y-Z plane using their preferred lead angle values, ensuring consistent chip thickness during roughing operations.

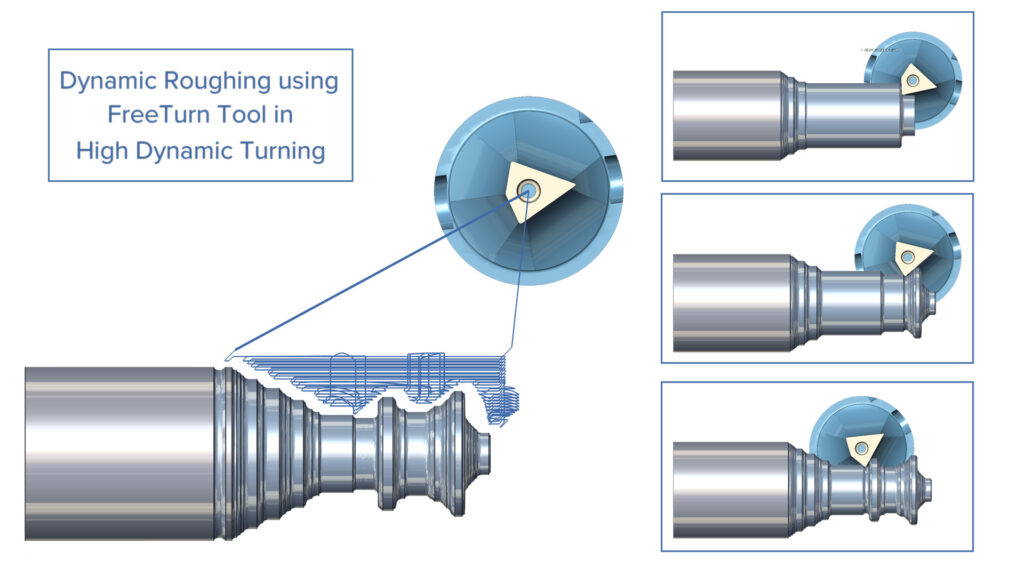

Turning | High Dynamic Turning

Dynamic Roughing in High Dynamic Turning

Challenge: With conventional turning, multiple tools were required for machining contours, leading to higher tool costs and longer cycle times due to frequent tool changes. Creating toolpaths in the Y-Z plane was not possible.

Solution: The Dynamic Roughing feature allows the FreeTurn tool to rotate freely around its axis, enabling cutting in small areas that are otherwise inaccessible with the preferred lead angle. The toolpath tries to maintain the tool orientation as close to the preferred lead angle as possible.

Benefits: With this new roughing feature, dynamic tool rotation enables a single roughing operation to machine complex shapes, eliminating the need for multiple processes, such as turning and grooving, with conventional turning tools.

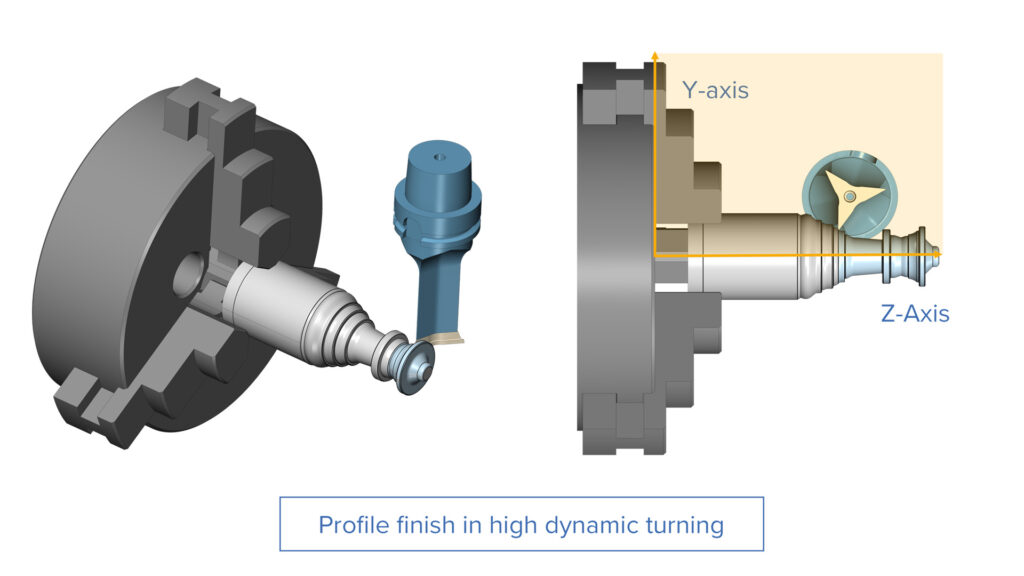

Turning | High Dynamic Turning

Profile Finish in High Dynamic Turning

Challenge: In conventional turning, multiple tools were required for machining contours, resulting in higher tool costs and increased cycle times due to frequent tool changes. Additionally, generating toolpaths in the Y-Z plane was not possible.

Solution: Using this new feature with the FreeTurn tool eliminates the need for multiple tools, and toolpaths can now be created in the Y-Z plane.

Benefits: This feature allows all contours of a workpiece to be machined in a single operation, significantly reducing cycle time by minimizing air cuts and tool changes — by up to 90%. It also enables up to 40% higher feed rates and delivers improved surface quality.

Simulation

Simulation SDK | Cutting Simulation

Pixel-Perfect GPU Renderer

Challenge: Standard rendering modes struggle to provide accurate visuals needed for high-precision machining and fine-detail inspection.

Solution: Leverage GPU acceleration to generate a pixel-perfect rendering when the camera is static to ensure a detailed and accurate visual representation of the current stock state.

Benefits: This enhancement supports more reliable inspection by providing sharper visuals and clearer deviation results.

Discover the many other new enhancements in this release.