Simulation

State-of-the-art simulation technology

ModuleWorks provides full kinematic simulation with collision checking and material removal simulation with scalable performance and usability. The simulation component runs on Microsoft Windows-based desktop systems as well as Linux-based machine controllers located on the machine tool (depending on your hardware and software requirements). CNC simulation tools are independent of our toolpath generation components and can be used with any toolpaths or backplot NC code.

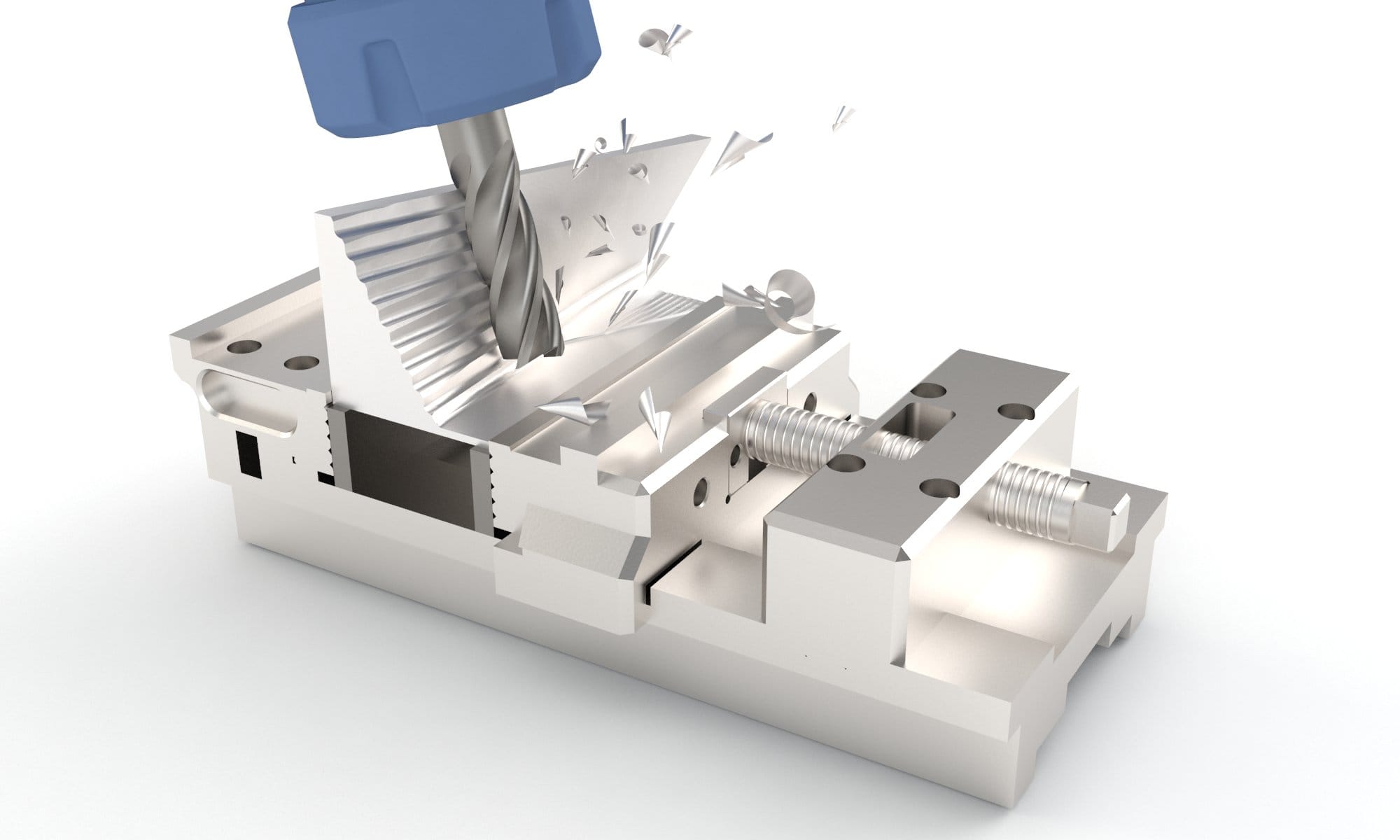

Cutting Simulation

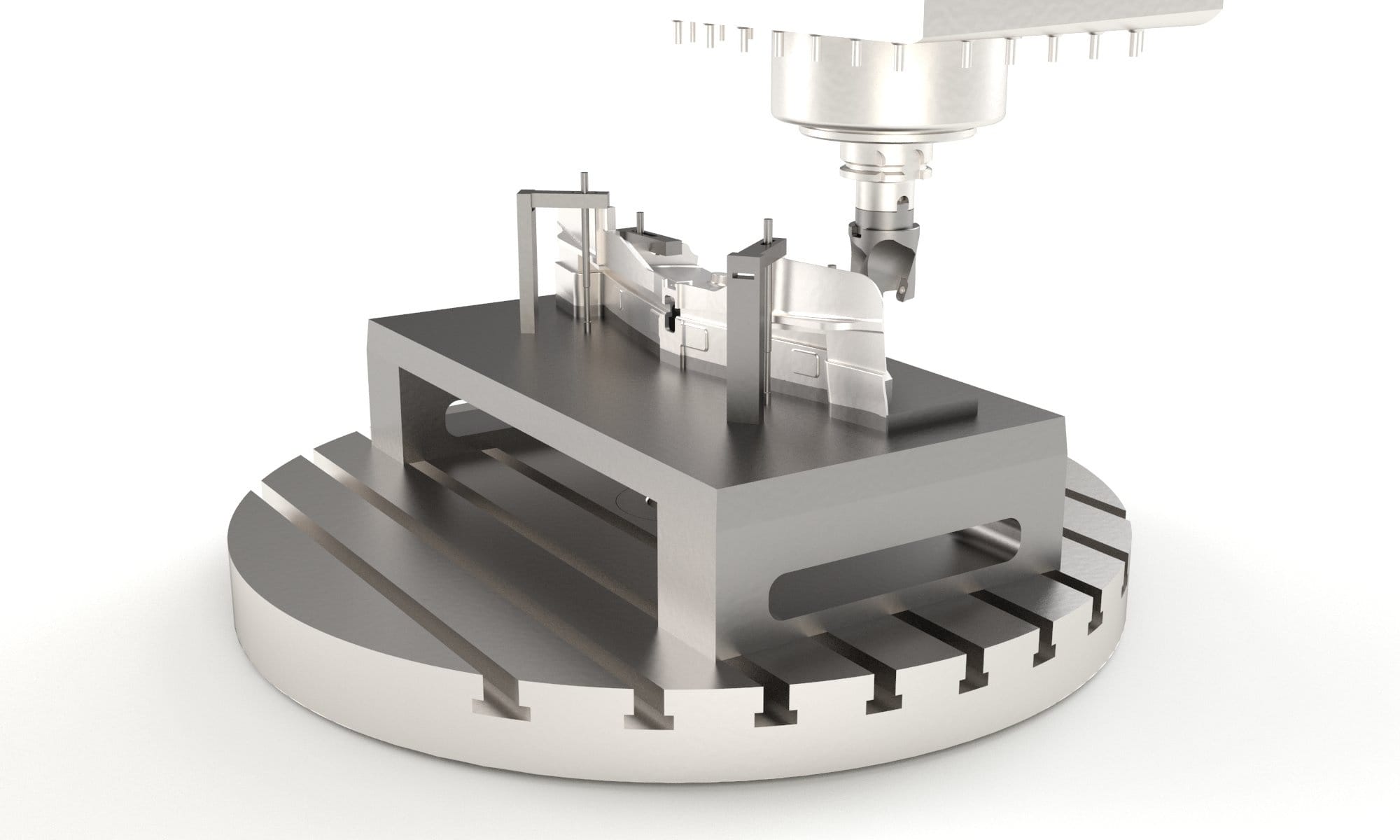

Machine Simulation

CNC Simulation

Let the Numbers Talk

market share worldwide

make us the world market leader in CAM technology.

customers

trust in the quality of our products and value our partnership.

years of ModuleWorks

are just the beginning.

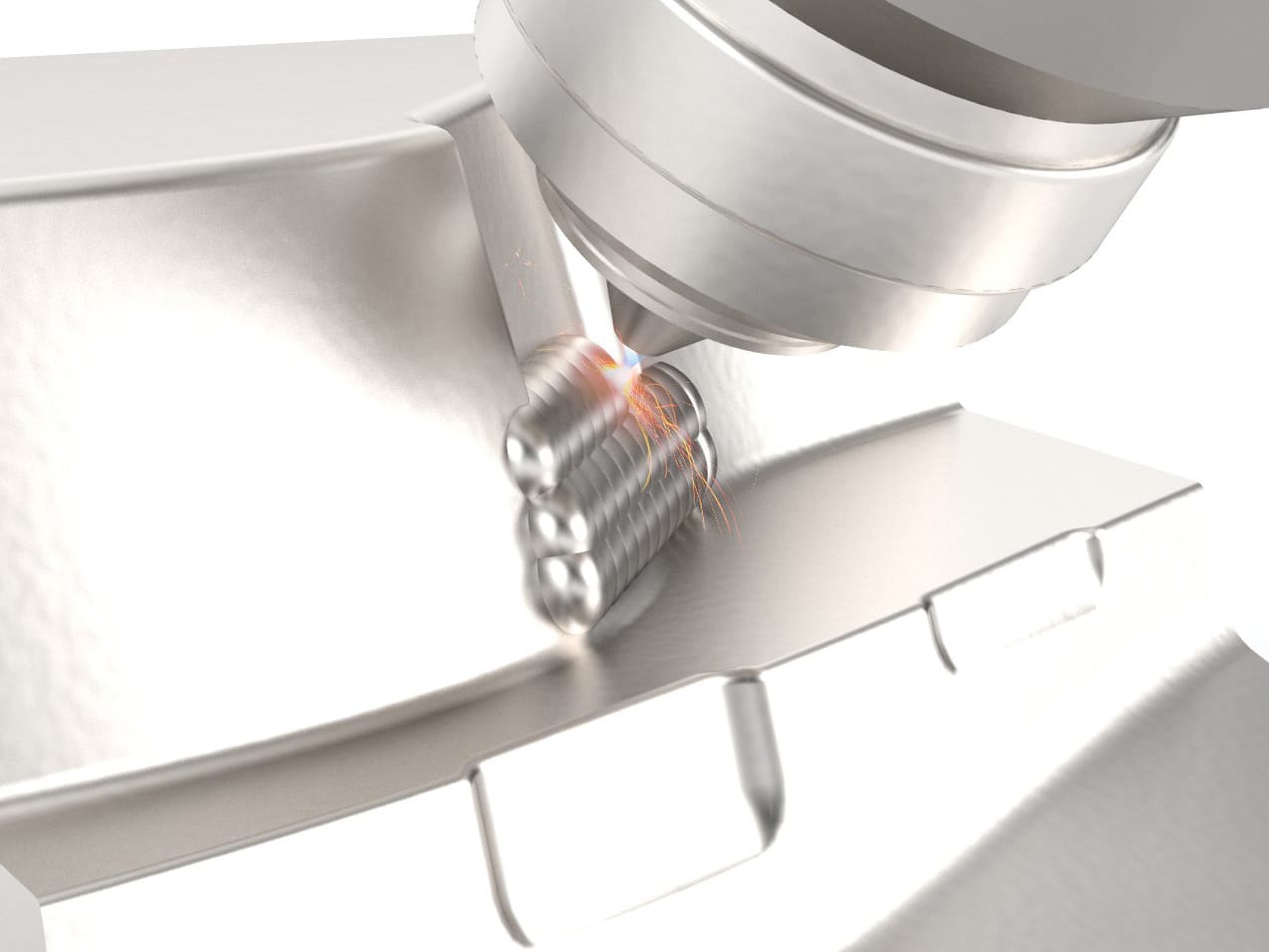

Additive Simulation

Additive processes are now common-place in CAM applications. Multi-axis machines and robots are becoming equipped with additive heads that enable new parts to be built from scratch or existing parts to be repaired. The complexity is similar to 5-axis milling where a full machine simulation is needed to oversee all the processes.

AddSim lets you simulate the process of adding material. With this hybrid technology you can seamlessly switch between adding and subtracting material for any type of machine, tool and process.